Page 51 - Practical Control Engineering a Guide for Engineers, Managers, and Practitioners

P. 51

26 Chapter Two

1.2

1

::s

.& 0.8

g 0.6

~ 0.4

e 0.2

Q..

0

0 10 20 30 40 50 60 70 80 90 100

1

&_o.s

.5 0.6

(/)

] ~:~

0-

0 10 20 30 40 50 60 70 80 90 100

Time (sec)

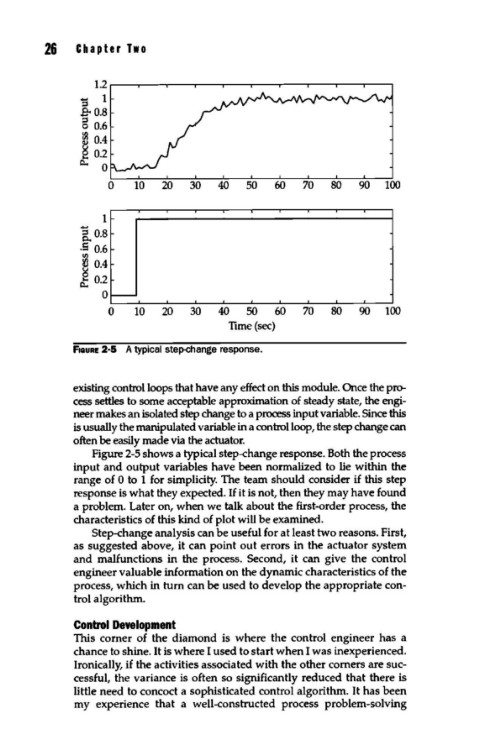

fiGURE 2·5 A typical step-change response.

existing control loops that have any effect on this module. Once the pr<r

cess settles to some acceptable approximation of steady state, the engi-

neer makes an isolated step change to a process input variable. Since this

is usually the manipulated variable in a control loop, the step change can

often be easily made via the actuator.

Figure 2-5 shows a typical step-change response. Both the process

input and output variables have been normalized to lie within the

range of 0 to 1 for simplicity. The team should consider if this step

response is what they expected. If it is not, then they may have found

a problem. Later on, when we talk about the first-order process, the

characteristics of this kind of plot will be examined.

Step-change analysis can be useful for at least two reasons. First,

as suggested above, it can point out errors in the actuator system

and malfunctions in the process. Second, it can give the control

engineer valuable information on the dynamic characteristics of the

process, which in turn can be used to develop the appropriate con-

trol algorithm.

Control Development

This corner of the diamond is where the control engineer has a

chance to shine. It is where I used to start when I was inexperienced.

Ironically, if the activities associated with the other corners are suc-

cessful, the variance is often so significantly reduced that there is

little need to concoct a sophisticated control algorithm. It has been

my experience that a well-constructed process problem-solving