Page 70 - Practical Control Engineering a Guide for Engineers, Managers, and Practitioners

P. 70

Basic Concepts in Process Analysis 45

and to manipulate U in proportion to the error, that is,

U = ke = k(S- Y) (3-17)

where k is the proportional control gain.

Before proceeding, let's think about Eq. (3-17) with reference to

the water tank. Assume that initially Y is equal to the set pointS so

that e is initially zero. Also, assume that the nominal initial values

have been subtracted from all of the quantities, so Y, S, e, and U are

initially zero. If S is stepped up, then e would become nonzero and

positive. This would mean that U would increase, assuming that k is

positive. An increase in U means more flow into the tank and the

level Y should rise. Okay, at least the control algorithm has the correct

signs and moves the controller output in the right direction.

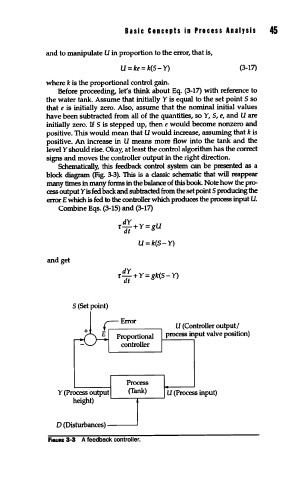

Schematically, this feedback control system can be presented as a

block diagram (Fig. 3-3). This is a classic schematic that will reappear

many times in many forms in the balance of this book. Note how the pro-

cess output Y is fed back and subtracted from the set pointS producing the

errorE which is fed to the controller which produces the process input U.

Combine Eqs. (3-15) and (3-17)

dY

fdt+Y=gU

U=k(S- Y)

and get

dY

f-+Y=gk(S- Y)

dt

S (Set point)

U (Controller output/

process input valve position)

Proportional

controller

Process

Y (Process output (Tank) U (Process input)

height) L..-----r---.J

D (Disturbances)------'

F1auRE 3-3 A feedback controller.