Page 131 - Practical Design Ships and Floating Structures

P. 131

106

The general advantages of catamaran ships could be still further improved by properly combining the

hull itself supported by buoyancy and the hydrofoil system which produces dynamic lift. During

normal sailing, desired part of the ship hull would be lifted up above free-surface by the dynamic lift.

Therefore, hull resistance would be decreased and ship speed could be increased. Furthermore, the foil

system significantly improves ship’s seakeeping quality in heavy weather, since the system acts as the

motion control device.

The 3-stage super-high-speed ship R & D Program has been completed successllly. Numerous

research reports and papers have been prepared and presented[ 1 - 91. This study is the third stage(the

final stage) research work and deals with the conceptual design of OLarge-Size Super-High-speed

Foil Catamaran ContainershipO. Actually, conceptual design works for 4 different ships have been

carried out in the final stage study, that is, about 1,000 TEU - 60 knot ship and about 4,000 TEU - 50,

60 and 70 knot ships. Due to limited space, however, only the brief summary of the design features for

4,000 TEU - 60 knot foil-catamaran containership shall be presented and discussed in this paper.

2 SELECTION OF MAIN CHARACTERISTICS

Catamaran ships have many practical advantages such as large deck area, high stability, superior

maneuverability, easy operation and maintenance, etc. Different from conventional mono hull ships,

therefore, the container loading capacity(number of containers) for catamaran ships is not determined

by deck area or stability, but by weight. The average weight of 7.5 tonnes per 20-foot container was

selected in this study. To determine ship length and breadth, about 4,000 twenty-foot size containers

were arranged on the deck. From this investigation, appropriate ranges of ship length(LPP) and

breadth(BR) were obtained.

Hull weight was estimated iteratively. Higher tensile steel(AH32) was selected as hull material. Main

engines were selected from the power estimation made from the results of the previous studies[9]. The

amount of he1 was calculated with the selected engine and the estimated power. All the weight

components were summed up to figure out the overall ship weight, that is, ship’s displacement. The

above procedure had to be repeated several times.

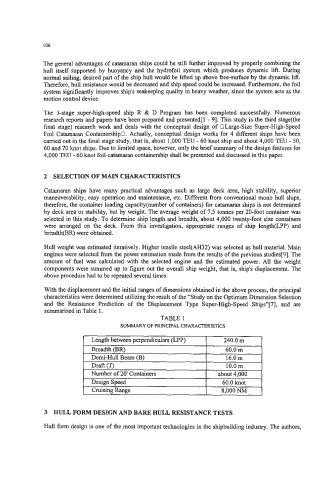

With the displacement and the initial ranges of dimensions obtained in the above process, the principal

characteristics were determined utilizing the result of the “Study on the Optimum Dimension Selection

and the Resistance Prediction of the Displacement Type Super-High-speed Ships”[7], and are

summarized in Table 1.

TABLE 1

SUMMARY OF PRlNCIPAL CHARACTERISTICS

Length between perpendiculars (LPP) 240.0 m

Breadth (BR) 60.0 m -

Demi-Hull Beam (€3) 16.0 m

Draft (T) 10.0 m -

Number of 20’ Containers about 4,000 -

Design Speed 60.0 knot

Cruising Range 8,000 NM

3 HULL FORM DESIGN AND BARE HULL RESISTANCE TESTS

Hull form design is one of the most important technologies in the shipbuilding industry. The authors,