Page 368 - Practical Design Ships and Floating Structures

P. 368

343

Figure 1 : Concept of an information system for damages of ship structures

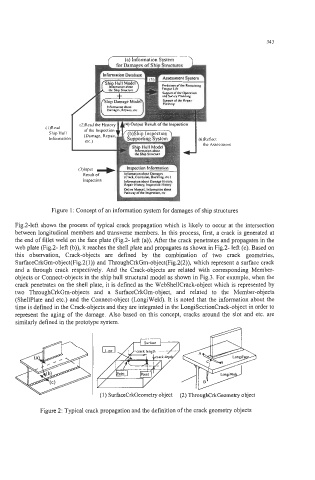

Fig.2-left shows the process of typical crack propagation which is likely to occur at the intersection

between longitudinal members and transverse members. In this process, first, a crack is generated at

the end of fillet weld on the face plate (Fig.2- left (a)). After the crack penetrates and propagates in the

web plate (Fig.2- left (b)), it reaches the shell plate and propagates as shown in Fig.2- left (c). Based on

this observation, Crack-objects are defined by the combination of two crack geometries,

SurfaceCrkGm-object(Fig.2( 1)) and ThroughCrkGm-object(Fig.2(2)), which represent a surface crack

and a through crack respectively. And the Crack-objects are related with corresponding Member-

objects or Connect-objects in the ship hull structural model as shown in Fig.3. For example, when the

crack penetrates on the shell plate, it is defined as the WebShellCrack-object which is represented by

two ThroughCrkGm-objects and a SurfaceCrkGm-object, and related to the Member-objects

(Shellplate and etc.) and the Connect-object (LongiWeld). It is noted that the information about the

time is defined in the Crack-objects and they are integrated in the LongiSectionCrack-object in order to

represent the aging of the damage. Also based on this concept, cracks around the slot and etc. are

similarly defined in the prototype system.

cpf=,f=g

Surface

.. _. -

Q~. ..

omf Point

(1) SurfaceCrkGeometry object

Figure 2: Typical crack propagation and the definition of the crack geometry objects