Page 372 - Practical Design Ships and Floating Structures

P. 372

341

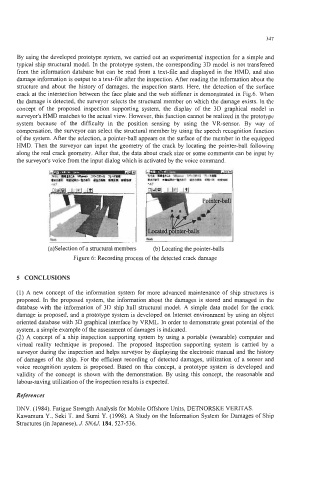

By using the developed prototype system, we carried out an experimental inspection for a simple and

typical ship structural model. In the prototype system, the corresponding 3D model is not transferred

from the information database but can be read from a text-file and displayed in the HMD, and also

damage information is output to a text-file after the inspection. After reading the information about the

structure and about the history of damages, the inspection starts. Here, the detection of the surface

crack at the intersection between the face plate and the web stiffener is demonstrated in Fig.6. When

the damage is detected, the surveyor selects the structural member on which the damage exists. In the

concept of the proposed inspection supporting system, the display of the 3D graphical model in

surveyor's HMD matches to the actual view. However, this function cannot be realized in the prototype

system because of the difficulty in the position sensing by using the VR-sensor. By way of

compensation, the surveyor can select the structural member by using the speech recognition function

of the system. After the selection, a pointer-ball appears on the surface of the member in the equipped

HMD. Then the surveyor can input the geometry of the crack by locating the pointer-ball following

along the real crack geometry. After that, the data about crack size or some comments can be input by

the surveyor's voice from the input dialog which is activated by the voice command.

Rhmi mua--U'Ji 1'Wm Lunn lnOQ

". '

r**

4r-.. -

(a)Selection of a structural members (b) Locating the pointer-balls

Figure 6: Recording process of the detected crack damage

5 CONCLUSIONS

(1) A new concept of the information system for more advanced maintenance of ship structures is

proposed. In the proposed system, the information about the damages is stored and managed in the

database with the information of 3D ship hull structural model. A simple data model for the crack

damage is proposed, and a prototype system is developed on Internet environment by using an object

oriented database with 3D graphical interface by VRML. In order to demonstrate great potential of the

system, a simple example of the assessment of damages is indicated.

(2) A concept of a ship inspection supporting system by using a portable (wearable) computer and

virtual reality technique is proposed. The proposed inspection supporting system is carried by a

surveyor during the inspection and helps surveyor by displaying the electronic manual and the history

of damages of the ship. For the efficient recording of detected damages, utilization of a sensor and

voice recognition system is proposed. Based on this concept, a prototype system is developed and

validity of the concept is shown with the demonstration. By using this concept, the reasonable and

labour-saving utilization of the inspection results is expected.

References

DNV. (1984). Fatigue Strength Analysis for Mobile Offshore Units, DETNORSKE VERITAS.

Kawamura Y., Seki T. and Sumi Y. (1998). A Study on the Information System for Damages of Ship

Structures (in Japanese), J. SNAJ. 184,527-536.