Page 430 - Practical Design Ships and Floating Structures

P. 430

405

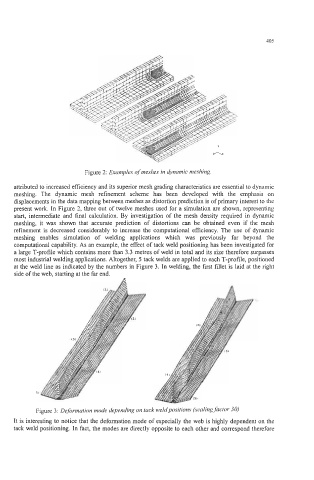

Figure 2: Examples of meshes in dynamic meshing.

attributed to increased efficiency and its superior mesh grading characteristics are essential to dynamic

meshing. The dynamic mesh refinement scheme has been developed with the emphasis on

displacements in the data mapping between meshes as distortion prediction is of primary interest to the

present work. In Figure 2, three out of twelve meshes used for a simulation are shown, representing

start, intermediate and final calculation. By investigation of the mesh density required in dynamic

meshing, it was shown that accurate prediction of distortions can be obtained even if the mesh

refinement is decreased considerably to increase the computational efficiency. The use of dynamic

meshing enables simulation of welding applications which was previously far beyond the

computational capability. As an example, the effect of tack weld positioning has been investigated for

a large T-profile which contains more than 3.3 metres of weld in total and its size therefore surpasses

most industrial welding applications. Altogether, 5 tack welds are applied to each T-profile, positioned

at the weld line as indicated by the numbers in Figure 3. In welding, the first fillet is laid at the right

side of the web, starting at the far end.

Figure 3: Deformation mode depending on tack weld positions (scaling factor 30)

It is interesting to notice that the deformation mode of especially the web is highly dependent on the

tack weld positioning. In fact, the modes are directly opposite to each other and correspond therefore