Page 432 - Practical Design Ships and Floating Structures

P. 432

407

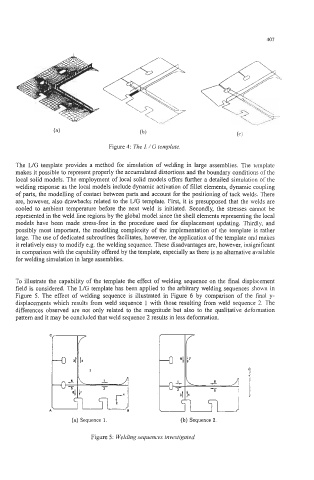

Figure 4: The L / G template

The WG template provides a method for simulation of welding in large assemblies. The template

makes it possible to represent properly the accumulated distortions and the boundary conditions of the

local solid models. The employment of local solid models offers further a detailed simulation of the

welding response as the local models include dynamic activation of fillet elements, dynamic coupling

of parts, the modelling of contact between parts and account for the positioning of tack welds. There

are, however, also drawbacks related to the WG template. First, it is presupposed that the welds are

cooled to ambient temperature before the next weld is initiated. Secondly, the stresses cannot be

represented in the weld line regions by the global model since the shell elements representing the local

models have been made stress-free in the procedure used for displacement updating. Thirdly, and

possibly most important, the modelling complexity of the implementation of the template is rather

large. The use of dedicated subroutines facilitates, however, the application of the template and makes

it relatively easy to modify e.g. the welding sequence. These disadvantages are, however, insignificant

in comparison with the capability offered by the template, especially as there is no alternative available

for welding simulation in large assemblies.

To illustrate the capability of the template the effect of welding sequence on the final displacement

field is considered. The L/G template has been applied to the arbitrary welding sequences shown in

Figure 5. The effect of welding sequence is illustrated in Figure 6 by comparison of the final y-

displacements which results from weld sequence 1 with those resulting from weld sequence 2. The

differences observed are not only related to the magnitude but also to the qualitative deformation

pattern and it may be concluded that weld sequence 2 results in less deformation.

(a) Sequence 1. (b) Sequence 2.

Figure 5 : Welding sequences investigated.