Page 102 - Practical Machinery Management for Process Plants Major Process Equipment Maintenance and Repair

P. 102

Installation, Maintenance, and Repair of Vertical Pumps 87

7. Install the packing gland and draw the gland nuts hand tight. Do not

compress the packing.

8. When a pump is first operated with new packing, it should be loose

enough to allow a small stream of liquid to flow from the gland.

There should be no leakage around the OD of the packing. Do not

operate the pump with packing too tightly compressed, and do not

make final adjustment until the pump has been operated for several

hours. Then tighten the gland nuts alternately, very slowly and

evenly, until the leakage rate is reduced to a steady drip. Gland nuts

should be tightened 1/6 turn (one flat) at a time and the packing leak-

age observed for 10 minutes before tightening another 1/6 turn.

9. Check the gland temperature and loosen the gland nuts to increase

the leakage rate if overheating of the packing is observed. The

gland adjustment should be checked periodically and readjusted as

needed.

Note: Refer also to the packing instructions in Chapter 8 of Volume 2.

Maintenance and Repair of Pump Bearings

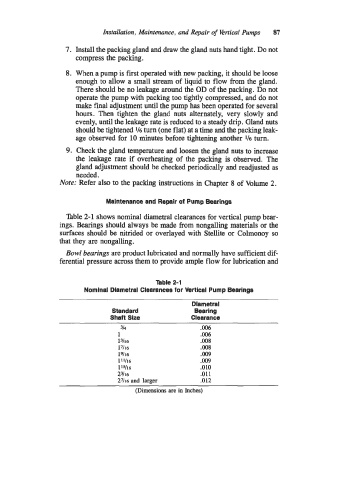

Table 2-1 shows nominal diametral clearances for vertical pump bear-

ings. Bearings should always be made from nongalling materials or the

surfaces should be nitrided or overlayed with Stellite or Colmonoy so

that they are nongalling.

Bowl bearings are product lubricated and normally have sufficient dif-

ferential pressure across them to provide ample flow for lubrication and

Table 2-1

Nominal Diametral Clearances for Vertical Pump Bearings

Diametral

Standard Bearing

Shaft Slre Clearance

314 .006

1 .006

13/16 .008

l7/I6 .008

19/16 .009

1l1/16 .009

115116 ,010

23/16 .011

27/16 and larger .012

(Dimensions are in Inches)