Page 99 - Practical Machinery Management for Process Plants Major Process Equipment Maintenance and Repair

P. 99

84 Major Process Equipment Maintenance and Repair

1

i

-IMPELLER

RAISE

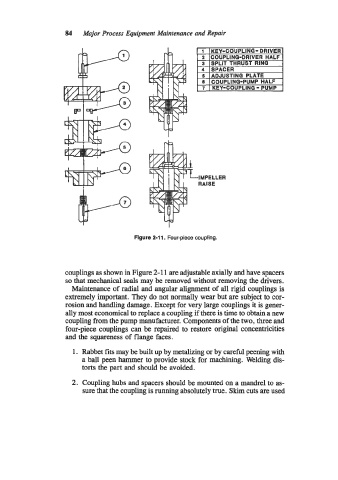

Figure 2-1 1. Four-piece coupling.

couplings as shown in Figure 2-1 1 are adjustable axially and have spacers

so that mechanical seals may be removed without removing the drivers.

Maintenance of radial and angular alignment of all rigid couplings is

extremely important. They do not normally wear but are subject to cor-

rosion and handling damage. Except for very large couplings it is gener-

ally most economical to replace a coupling if there is time to obtain a new

coupling from the pump manufacturer. Components of the two, three and

four-piece couplings can be repaired to restore original concentricities

and the squareness of flange faces.

1. Rabbet fits may be built up by metalizing or by careful peening with

a ball peen hammer to provide stock for machining. Welding dis-

torts the part and should be avoided.

2. Coupling hubs and spacers should be mounted on a mandrel to as-

sure that the coupling is running absolutely true. Skim cuts are used