Page 97 - Practical Machinery Management for Process Plants Major Process Equipment Maintenance and Repair

P. 97

02 Major Process Equipment Maintenance and Repair

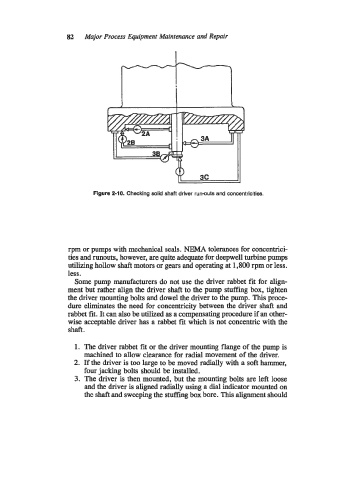

Figure 2-10. Checking solid shaft driver run-outs and concentricities.

rpm or pumps with mechanical seals. NEMA tolerances for concentrici-

ties and runouts, however, are quite adequate for deepwell turbine pumps

utilizing hollow shaft motors or gears and operating at 1,800 rpm or less.

less.

Some pump manufacturers do not use the driver rabbet fit for align-

ment but rather align the driver shaft to the pump stuffing box, tighten

the driver mounting bolts and dowel the driver to the pump. This proce-

dure eliminates the need for concentricity between the driver shaft and

rabbet fit. It can also be utilized as a compensating procedure if an other-

wise acceptable driver has a rabbet fit which is not concentric with the

shaft.

1. The driver rabbet fit or the driver mounting flange of the pump is

machined to allow clearance for radial movement of the driver.

2. If the driver is too large to be moved radially with a soft hammer,

four jacking bolts should be installed.

3. The driver is then mounted, but the mounting bolts are left loose

and the driver is aligned radially using a dial indicator mounted on

the shaft and sweeping the stuffing box bore. This alignment should