Page 125 - Practical Machinery Management for Process Plants Major Process Equipment Maintenance and Repair

P. 125

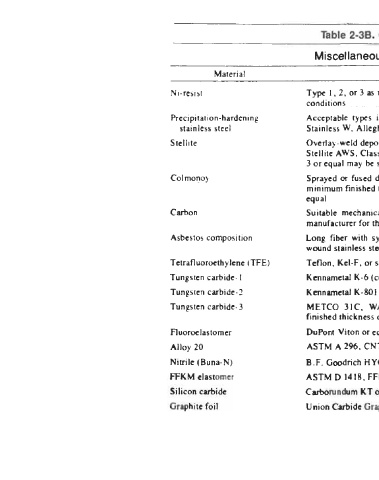

Table 2-38. Continued.

Miscellaneous Materials

Material Typical Description

Ni-resist Type I, 2, or 3 as recommended by International Nickel Co. for sen ice

conditions

Precipitation-hardening Acceptable types include ARMCO 17-7 PH and 17-4 PH. U.S. Steel

stainless steel Stainless W. Allegheny Ludlum AM 350 and AM 355

Stellite Overlay-weld deposit of '& inch minimum finished thickness of Haynes

Stellite AWS, Class RCoCr-C. RCoCr-A, orequal; solid cast stellite No.

3 or equal may be substituted for an overlayed pan

Colmonoy Sprayed or fused deposit of 0.010 inch or gas-weld deposit of Ya inch

minimum finished thickness of Wall-Colmonoy AWS, Class RNiCr-C or

equal

Carbon Suitrble mechanical cubon as recornmended by the mechanical seal

manufacturer for the service

Asbestos composition Long fiber with synthetic rubber binder suitable for 750 F. or spiral-

wound stainless steel and asbestos

Tetrafluoroethy lene (TFE) Teflon, Kel-F. or similar material

Tungsten carbide- I Kmnametd K-6 (cobalt binder) or equal (solid pan. not overlay)

Tungsten carbide-? Kmnametd K-801 (nickel binder) or qual (solid pan. not overlay)

Tungsten carbide-3 METCO 3lC. WALLEX 55, or equal (sprayed overlay; minimum s

finished thickness of 0.03inch) Y

2.

Fluomlastomer DuPont Viton or equal B

b

Alloy 20 ASTM A 2%. CN7M; Carpenter 20CB3; or qual 3

Nitrile (Buna-N) B.F. Goodrich HYCAR or equal 2

FFKM elastomer ASTM D 14 18. FFKM elastomer; DuPont Kalrez; or equal

Silicon carbide Carborundum KT or qual CI

0

Graphite foil Union Carbide Graphoil or qual \9