Page 128 - Practical Machinery Management for Process Plants Major Process Equipment Maintenance and Repair

P. 128

PRESSING MOTION MUST

BE CONTINUOUS

ARBOR PRESS OR

HYDRAULIC PRESS

HOUS INQ STEPPED ARBOR

OR MANDREL

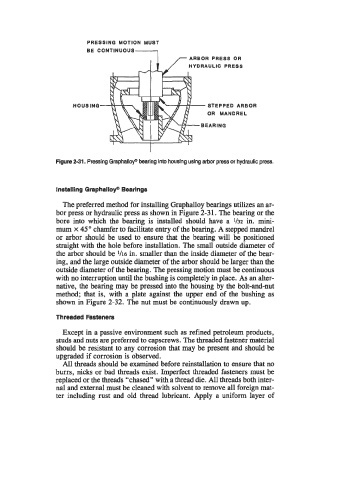

Figure 2-31. Pressing Graphallw bearing into housing using arbor press or hydraulic press.

Installing Graphalloy@ Bearlngs

The preferred method for installing Graphalloy bearings utilizes an ar-

bor press or hydraulic press as shown in Figure 2-3 1. The bearing or the

bore into which the bearing is installed should have a 1/32 in. mini-

mum X 45’ chamfer to facilitate entry of the bearing. A stepped mandrel

or arbor should be used to ensure that the bearing will be positioned

straight with the hole before installation. The small outside diameter of

the arbor should be 1/16 in. smaller than the inside diameter of the bear-

ing, and the large outside diameter of the arbor should be larger than the

outside diameter of the bearing. The pressing motion must be continuous

with no interruption until the bushing is completely in place. As an alter-

native, the bearing may be pressed into the housing by the bolt-and-nut

method; that is, with a plate against the upper end of the bushing as

shown in Figure 2-32. The nut must be continuously drawn up.

Threaded Fasteners

Except in a passive environment such as refined petroleum products,

studs and nuts are preferred to capscrews. The threaded fastener material

should be resistant to any corrosion that may be present and should be

upgraded if corrosion is observed.

All threads should be examined before reinstallation to ensure that no

burrs, nicks or bad threads exist. Imperfect threaded fasteners must be

replaced or the threads “chased” with a thread die. All threads both inter-

nal and external must be cleaned with solvent to remove all foreign mat-

ter including rust and old thread lubricant. Apply a uniform layer of