Page 129 - Practical Machinery Management for Process Plants Major Process Equipment Maintenance and Repair

P. 129

112 Major Process Equipment Maintenunce and Repair

HREADED BOLT

HOUSING PLATE

BEARING

ROTATION OF NUT

MUST BE CONTINUOUS

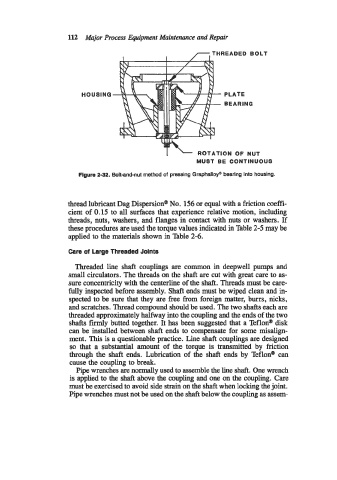

Figure 2-32. Bolt-and-nut method of pressing Graphallop bearing into housing.

thread lubricant Dag Dispersion@ No. 156 or equal with a friction coeffi-

cient of 0.15 to all surfaces that experience relative motion, including

threads, nuts, washers, and flanges in contact with nuts or washers. If

these procedures are used the torque values indicated in Table 2-5 may be

applied to the materials shown in Table 2-6.

Care of Large Threaded Joints

Threaded line shaft couplings are common in deepwell pumps and

small circulators. The threads on the shaft are cut with great care to as-

sure concentricity with the centerline of the shaft. Threads must be care-

fully inspected before assembly. Shaft ends must be wiped clean and in-

spected to be sure that they are free from foreign matter, burrs, nicks,

and scratches. Thread compound should be used. The two shafts each are

threaded approximately halfway into the coupling and the ends of the two

shafts firmly butted together. It has been suggested that a Teflon@ disk

can be installed between shaft ends to compensate for some misalign-

ment. This is a questionable practice. Line shaft couplings are designed

so that a substantial amount of the torque is transmitted by friction

through the shaft ends. Lubrication of the shaft ends by Teflon@ can

cause the coupling to break.

Pipe wrenches are normally used to assemble the line shaft. One wrench

is applied to the shaft above the coupling and one on the coupling. Care

must be exercised to avoid side strain on the shaft when locking the joint.

Pipe wrenches must not be used on the shaft below the coupling as assem-