Page 132 - Practical Machinery Management for Process Plants Major Process Equipment Maintenance and Repair

P. 132

Installation, Maintenance, and Repair of Wrtical Pumps 115

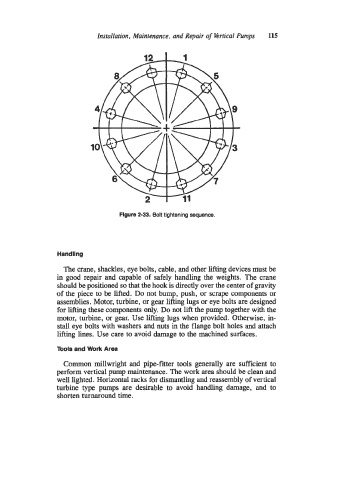

Figure 2-33. Bolt tightening sequence.

Handling

The crane, shackles, eye bolts, cable, and other lifting devices must be

in good repair and capable of safely handling the weights. The crane

should be positioned so that the hook is directly over the center of gravity

of the piece to be lifted. Do not bump, push, or scrape components or

assemblies. Motor, turbine, or gear lifting lugs or eye bolts are designed

for lifting these components only. Do not lift the pump together with the

motor, turbine, or gear. Use lifting lugs when provided. Otherwise, in-

stall eye bolts with washers and nuts in the flange bolt holes and attach

lifting lines. Use care to avoid damage to the machined surfaces.

Tools and Work Area

Common millwright and pipe-fitter tools generally are sufficient to

perform vertical pump maintenance. The work area should be clean and

well lighted. Horizontal racks for dismantling and reassembly of vertical

turbine type pumps are desirable to avoid handling damage, and to

shorten turnaround time.