Page 162 - Practical Machinery Management for Process Plants Major Process Equipment Maintenance and Repair

P. 162

144 Major Process Equipment Maintenance and Repair

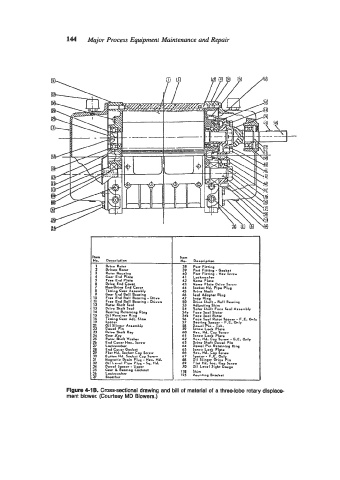

No. Dersrlpllm

Drive Rotor 38 Port Fitting

Driven Rotor Pnrt Fitting - Gaskmr

Rotor Housing Pcwi Fittine -Hex SE~W

Gear End Plat.

Fra. End Plate 42 Name Plate

Dtive End Lwer I 43 Nome Plot- Drive Screw

7 Nan-Drive End Cacr 14 Socket Hd. Pip Plug

8 Tirnin Gear Assnnbly 45 Drira Shaft

Gee, 2nd Boll B.m.ing 46 Seal Adopt- Ring

10 Fmc End Boll Bmmring - Drir. 47 Sncp Ring

11 Free End 8.11 6.mring - Dwiven 50 Drive Shaft - Ball Bearing

12 ROIW Shmft Sed 53 Adiurting Shim

13 Drir. Shaft Seal 54 Rotor Shdt Face k.1 Ass.mbly

14 Bcorinp Retoining Ring 5.4. Fmcc Sed Stata

1s Oil Retainer Ring 54b Face Sed RDIW

16 Timing Gem Adi. Shim

1-4 SF.C*.

21 Oil Slim VI Asscmblr

22 Cowal #in 59 Screw Lock Plate

23 Drive Shalt Key 60 Her. Hd. Ca Screw

24 Gear Xey 61 Screw Lock hmtm

25 Rmo, Shaft Washer 62 Hex. Hd. Cm Ssrcr - G.E. Only

26 End Corer H... Screw 63 Drive Shoft fiow.1 Pin

21 Lakwashw 64 Dowel Pin Retaining Ring

End Co.w Coska 65 Screw Lock Plate

Flat Hd. Sadto Ca kwcr 66 He.. Hd. Cop SF.."

Button Hd. Sock=# knr 67 Spmccv - F.E. On1

Mqmtic Dsoin Plug - He.. Hd. 6a oil Slimper Drive Fin

32 Oil Lerel Pipe Plug - Sq. Hd. 6P FInt Hd. SOC. Cmp krer

Dor.1 S - Upper 70 Oil Level Sight Gaupm

Ceo. 6 caring Locknut 118 Shim

LncCwoshe. 125 Lkwnting Bvockn

Flgure 4-16. Cross-sectional drawing and bill of material of a threelobe rotary dlsplace

ment blower. (Courtesy MD Blowers.)