Page 232 - Practical Machinery Management for Process Plants Major Process Equipment Maintenance and Repair

P. 232

214 Major Process Equipment Maintenance and Repair

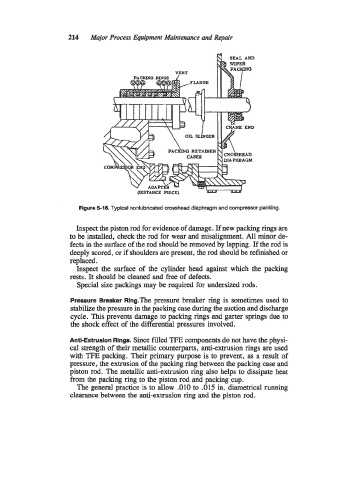

Figure 5-16. Typical nonlubricated crosshead diaphragm and compressor packing.

Inspect the piston rod for evidence of damage. If new packing rings are

to be installed, check the rod for wear and misalignment. All minor de-

fects in the surface of the rod should be removed by lapping. If the rod is

deeply scored, or if shoulders are present, the rod should be refinished or

replaced.

Inspect the surface of the cylinder head against which the packing

rests. It should be cleaned and free of defects.

Special size packings may be required for undersized rods.

Pressure Breaker Ring.The pressure breaker ring is sometimes used to

stabilize the pressure in the packing case during the suction and discharge

cycle. This prevents damage to packing rings and garter springs due to

the shock effect of the differential pressures involved.

Anti-Extruslon Rlngs. Since filled TFE components do not have the physi-

cal strength of their metallic counterparts, anti-extrusion rings are used

with TFE packing. Their primary purpose is to prevent, as a result of

pressure, the extrusion of the packing ring between the packing case and

piston rod. The metallic anti-extrusion ring also helps to dissipate heat

from the packing ring to the piston rod and packing cup.

The general practice is to allow .010 to .015 in. diametrical running

clearance between the anti-extrusion ring and the piston rod.