Page 230 - Practical Machinery Management for Process Plants Major Process Equipment Maintenance and Repair

P. 230

21 2 Major Process Equipment Maintenance and Repair

depressurized. Also, before installing the packing, record all identifying

markings from the case and packing for reference when replacing indi-

vidual components.

Operational break-in of a packing is very important. Improper break-

in can result in faulty sealing and damage to the piston rod. The following

points will in most cases assure proper break-in and operation. Break-in

time will vary depending upon conditions.

1. Cleanliness-The packing and rod must be clean! If the rod has any

nicks or corrosion in the area that will enter the packing, carefully

remove nicks and clean the rod.

2. Pressure-During the break-in period, it is advisable to gradually

increase the cylinder pressure and vary the operating speed if possi-

ble. This allows the packing to “wear-in” and to conform to the

piston rod before being subjected to full load pressure. Wear-in time

will be shortened if it is possible to operate at a low load, rather

than at no load. If during break-in, leakage or overheating appears

to be increasing, or out of control, reduce pressure and/or speed to

allow packing to stabilize. If this does not reduce leakage, the unit

should be stopped for packing inspection to determine the cause.

\

PACKING

CARTER

FLqNCE SFRINGS

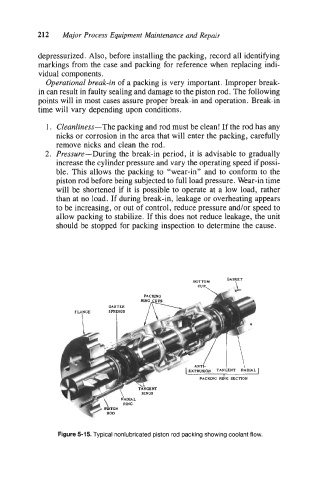

Figure 5-15. Typical nonlubricated piston rod packing showing coolant flow.