Page 225 - Practical Machinery Management for Process Plants Major Process Equipment Maintenance and Repair

P. 225

Reciprocating Gas Engines and Compressors 207

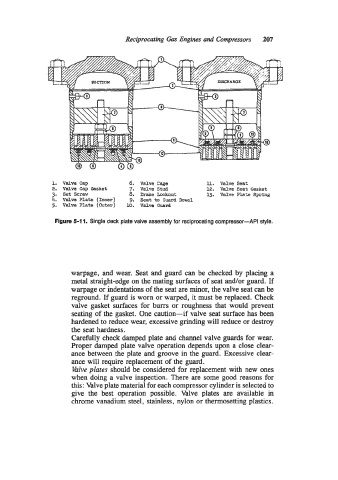

1. Valve Cap 6. Valve Cage ll. Valve Seat

2. Valve Cap Gasket 7. Valve Stud 12. Valve Seat Gasket

3. Set Screw 8. Drake Locknut 13. Valve Plate Spring

4. Valve Plate (Inner) 9. Seat to Guard Dowel

5. valve Plate (outer) 10. Vdve GU~JA

Figure 5-1 1. Single deck plate valve assembly for reciprocating compressor-AP1 style.

warpage, and wear. Seat and guard can be checked by placing a

metal straight-edge on the mating surfaces of seat and/or guard. If

warpage or indentations of the seat are minor, the valve seat can be

reground. If guard is worn or warped, it must be replaced. Check

valve gasket surfaces for bum or roughness that would prevent

seating of the gasket. One caution-if valve seat surface has been

hardened to reduce wear, excessive grinding will reduce or destroy

the seat hardness.

Carefully check damped plate and channel valve guards for wear.

Proper damped plate valve operation depends upon a close clear-

ance between the plate and groove in the guard. Excessive clear-

ance will require replacement of the guard.

Wve plates should be considered for replacement with new ones

when doing a valve inspection. There are some good reasons for

this: Valve plate material for each compressor cylinder is selected to

give the best operation possible. Valve plates are available in

chrome vanadium steel, stainless, nylon or thermosetting plastics.