Page 392 - Practical Machinery Management for Process Plants Major Process Equipment Maintenance and Repair

P. 392

TURBINE CASlNQ CARBON RlNQ

TOP HALF NE

HAFT

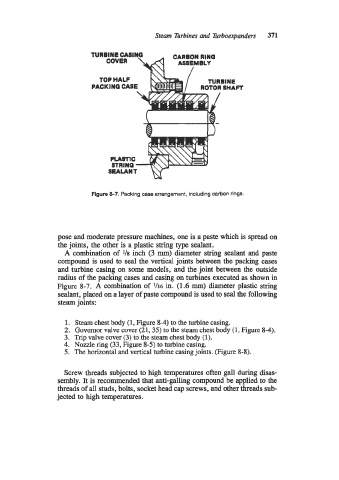

Fiiure 87. Packing case arrangement, including carbon rings.

pose and moderate pressure machines, one is a paste which is spread on

the joints, the other is a plastic string type sealant.

A combination of 1/s inch (3 mm) diameter string sealant and paste

compound is used to seal the vertical joints between the packing cases

and turbine casing on some models, and the joint between the outside

radius of the packing cases and casing on turbines executed as shown in

Figure 8-7. A combination of 1/16 in. (1.6 mm) diameter plastic string

sealant, placed on a layer of paste compound is used to seal the following

steam joints:

1. Steam chest body (1, Figure 8-4) to the turbine casing.

2. Governor valve cover (21,35) to the steam chest body (1, Figure 8-4).

3. Trip valve cover (3) to the steam chest body (1).

4. Nozzle ring (33, Figure 8-5) to turbine casing.

5. The horizontal and vertical turbine casing joints. (Figure 8-8).

Screw threads subjected to high temperatures often gall during disas-

sembly. It is recommended that anti-galling compound be applied to the

threads of all studs, bolts, socket head cap screws, and other threads sub-

jected to high temperatures.