Page 397 - Practical Machinery Management for Process Plants Major Process Equipment Maintenance and Repair

P. 397

Steam Turbines and Turboexpanders 375

Clearances

The inside diameters of new carbon rings are selected to match to the

maximum expected turbine exhaust temperature (Refer to Table 8-7).

The inside diameters of used carbon rings may be slightly larger than

new rings. Measuring the carbon rings is difficult, however, an inside

micrometer or snap gauges may be used with a fair degree of accuracy.

The cold clearances may be determined by measuring the inside diame-

ter of the assembled rings and the diameter of the rotor shaft at sealing

areas. The difference between the measurements is the cold diametral

clearance.

Adjustments

The carbon rings are not adjustable. Replacement is recommended if

excessive steam leaks from the packing cases. Packing case cleanliness is

of the utmost importance in achieving proper carbon ring seating. If an

air supply is available, blow out the packing cases before replacing the

carbon rings. For best results, install new carbon rings in complete sets.

Refer to pages 349 through 353 for break-in procedures.

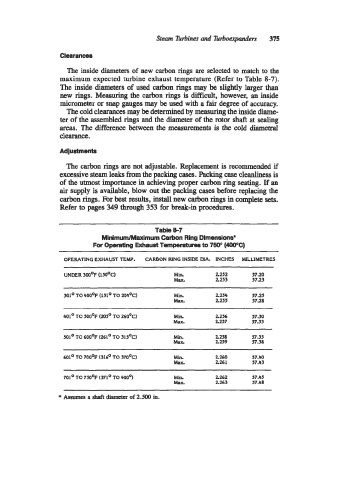

Table 8-7

Minimum/Maximum Cahon Ring Dimensions*

For Operating Exhaust Temperatures to 7500 (400%)

OPERATING EXHAUST TEMP. CARBON RING INSIDE DIA. INCHES MILLIMETRES

UNDER 300'F (150'C) Min. 2252 57.20

Max. 2.253 57.23

301' TO 400'F (151' TO 204'C) Min. 2254 57.25

Max. 2255 5738

401' TO 500'F (205' TO 260'C) Min. 2.256 57.30

Max. 2.257 57.33

501' TO 600'F (261' TO 315'C) Min. 2258 57.35

Max. 2259 57.38

601' TO 700'F (316' TO 370'C) Min. 2260 57.40

Max. 2261 57.13

701' TO 750'F (371' TO 400') Min. 2.262 57.45

Max. 2263 57.48

* Assumes a shaft diameter of 2.500 in.