Page 446 - Practical Machinery Management for Process Plants Major Process Equipment Maintenance and Repair

P. 446

424 Major Process Eipipment Maintenance and Repair

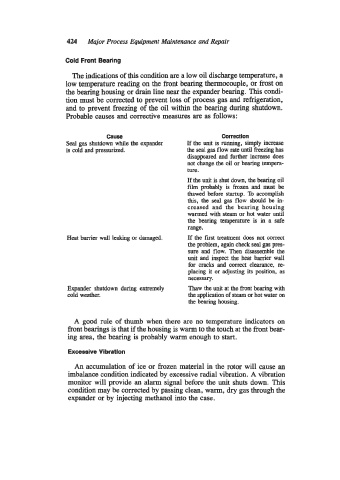

Cold Front Bearing

The indications of this condition are a low oil discharge temperature, a

low temperature reading on the front bearing thermocouple, or frost on

the bearing housing or drain line near the expander bearing. This condi-

tion must be corrected to prevent loss of process gas and refrigeration,

and to prevent freezing of the oil within the bearing during shutdown.

Probable causes and corrective measures are as follows:

Cause Correctfon

Seal gas shutdown while the expander If the unit is running, simply increase

is cold and pressurized. the seal gas flow rate until freezing has

disappeared and further increase does

not change the oil or bearing tempera-

ture.

If the unit is shut down, the bearing oil

film probably is frozen and must be

thawed before startup. To accomplish

this, the seal gas flow should be in-

creased and the bearing housing

warmed with steam or hot water until

the bearing temperature is in a safe

range.

Heat barrier wall leaking or damaged. If the first treatment does not correct

the problem, again check seal gas pres-

sure and flow. Then disassemble the

unit and inspect the heat barrier wall

for cracks and correct clearance, re-

placing it or adjusting its position, as

necessary.

Expander shutdown during extremely Thaw the unit at the front bearing with

cold weather. the application of steam or hot water on

the bearing housing.

A good rule of thumb when there are no temperature indicators on

front bearings is that if the housing is warm to the touch at the front bear-

ing area, the bearing is probably warm enough to start.

Excessive Vibration

An accumulation of ice or frozen material in the rotor will cause an

imbalance condition indicated by excessive radial vibration. A vibration

monitor will provide an alarm signal before the unit shuts down. This

condition may be corrected by passing clean, warm, dry gas through the

expander or by injecting methanol into the case.