Page 467 - Practical Machinery Management for Process Plants Major Process Equipment Maintenance and Repair

P. 467

444 Major Process Equipment Maintenance and Repair

address the basic parameters for that design. For a jet engine these are to

minimize frontal area through the use of long blades and a small hub di-

ameter, minimize combustor length and diameter to minimize drag and

overall engine length, and to ensure dimensional symmetry upon rapid

heat up and cool down. A jet utilizes turbine metallurgy and advand

cooling techniques to withstand the relatively short periods of time (take-

offs) during which the engine is fired hard. It must be recognized that an

aircraft engine typically spends 98 percent of its life operating in a clean,

cool atmosphere, burning a good clean fuel, and at a fraction of its rated

firing temperature. These factors all contribute to the high reliability we

have come to expect from jet engines.

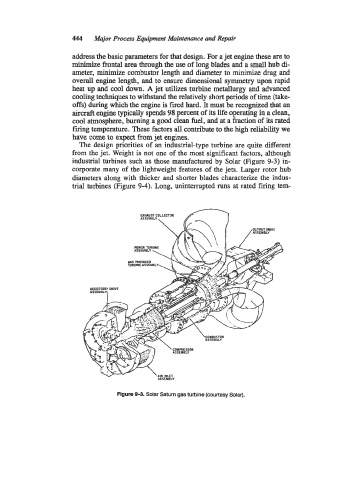

The design priorities of an industrial-type turbine are quite different

from the jet. Weight is not one of the most significant factors, although

industrial turbines such as those manufactured by Solar (Figure 9-3) in-

corporate many of the lightweight features of the jets. Larger rotor hub

diameters along with thicker and shorter blades characterize the indus-

trial turbines (Figure 9-4). Long, uninterrupted runs at rated firing tem-

Figure 9-3. Solar Saturn gas turbine (courtesy Solar).