Page 483 - Practical Machinery Management for Process Plants Major Process Equipment Maintenance and Repair

P. 483

460 Major Process Equipment Maintenance and Repair

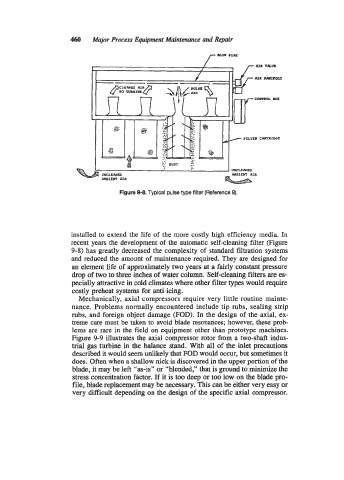

flgure 9-8. Typical pulse type fitter (Reference 9).

installed to extend the life of the more costly high efficiency media. In

recent years the development of the automatic self-cleaning filter (Figure

9-8) has greatly decreased the complexity of standard filtration systems

and reduced the amount of maintenance required. They are designed for

an element life of approximately two years at a fairly constant pressure

drop of two to three inches of water column. Self-cleaning filters are es-

pecially attractive in cold climates where other filter types would require

costly preheat systems for anti-icing.

Mechanically, axial compressors require very little routine mainte-

nance. Problems normally encountered include tip rubs, sealing strip

rubs, and foreign object damage (FOD). In the design of the axial, ex-

treme care must be taken to avoid blade resonances; however, these prob-

lems are rare in the field on equipment other than prototype machines.

Figure 9-9 illustrates the axial compressor rotor from a two-shaft indus-

trial gas turbine in the balance stand. With all of the inlet precautions

described it would seem unlikely that FOD would occur, but sometimes it

does. Often when a shallow nick is discovered in the upper portion of the

blade, it may be left “as-is” or “blended,” that is ground to minimize the

stress concentration factor. If it is too deep or too low on the blade pro-

file, blade replacement may be necessary. This can be either very easy or

very difficult depending on the design of the specific axial compressor.