Page 485 - Practical Machinery Management for Process Plants Major Process Equipment Maintenance and Repair

P. 485

462 Major Process Equipment Maintenance and Repair

units operating on liquid fuels. In line with most turbine manufacturers’

recommendations, the gas supplied should be free of particulate, contain

the minimum amount of hydrogen sulfide, and should be at least dry and

preferably have 20°F superheat at entry to the turbine fuel system.

In general, problems associated with gas fuel systems are either caused

by variations in the calorific value of the gas or by the condensation of

hydrocarbon liquids. Due care and attention should be paid to the design

and operation of the knock-out facilities associated with the gas turbine.

A secondary knock-out drum or inline cyclone separator should be in-

stalled as close to the turbine as possible, to eliminate any condensation

in the line from the primary knock-out facility.

Operation on distillate fuels such as diesel fuel generally does not pre-

sent a major problem. This type of fuel is usually free of the type of con-

taminants which cause hot corrosion of the turbine blades. Crude oil, on

the other hand, represents a serious risk of hot gas path corrosion if not

properly treated to remove the heavy metal contaminants which are usu-

ally present.

Life expectancies for combustion hardware operated on liquid fuels are

generally less than those which are operated on gaseous fuels. Gas tur-

bines operated on dual fuel, that is liquid and natural gas, suffer from

coke build-up in the liquid fuel nozzles if the liquid nozzles are not ade-

quately purged when not in use. Purging is usually done with air or natu-

ral gas.

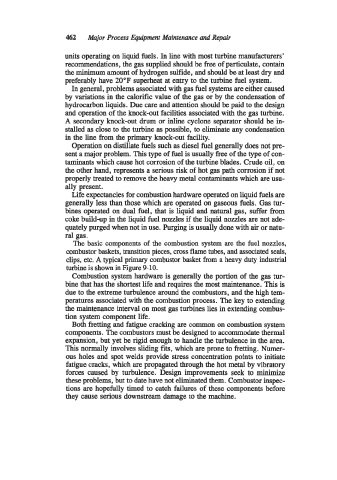

The basic components of the combustion system are the fuel nozzles,

combustor baskets, transition pieces, cross flame tubes, and associated seals,

clips, etc. A typical primary combustor basket from a heavy duty industrial

turbine is shown in Figure 9-10.

Combustion system hardware is generally the portion of the gas tur-

bine that has the shortest life and requires the most maintenance. This is

due to the extreme turbulence around the combustors, and the high tem-

peratures associated with the combustion process. The key to extending

the maintenance interval on most gas turbines lies in extending combus-

tion system component life.

Both fretting and fatigue cracking are common on combustion system

components. The combustors must be designed to accommodate thermal

expansion, but yet be rigid enough to handle the turbulence in the area.

This normally involves sliding fits, which are prone to fretting. Numer-

ous holes and spot welds provide stress concentration points to initiate

fatigue cracks, which are propagated through the hot metal by vibratory

forces caused by turbulence. Design improvements seek to minimize

these problems, but to date have not elirninated them. Combustor inspec-

tions are hopefully timed to catch failures of these components before

they cause serious downstream damage to the machine.