Page 65 - Practical Machinery Management for Process Plants Major Process Equipment Maintenance and Repair

P. 65

50 Practical Machinery Management for Process Plants

How and Why Centrifugal Pumps Continue to Fail

It is not within the scope of this text to discuss and analyze the obvious

differences in operating philosophies, priorities, workforce training, atti-

tudes, etc., that must exist in order to have ten failures at location “A” for

every single failure ar location “B”. Instead, this chapter outlines and

explains a range of tangible problems and failure causes a competent trou-

bleshooter must pursue and rectify if his or her plant is to become one of the

above-average performers. Some of these troubles are perhaps well known

but tend to be de-emphasized; others are truly elusive and, therefore, merit

close attention.

Selection-related Problems

Centrifugal pump impellers will usually perform well over a wide range

of flows and pressures. However, impellers designed for conditions of low

NPSHR, Net Positive Suction Head Required, at the suction eye vane tips

may suffer from recirculation when operating at low-flow conditions. Recir-

culation can occur at both the impeller inlet and outlet, and at very low

capacities will usually be present at both. Operation at lower than design

flows means operation at reduced efficiency: A higher proportion of the

power input will be converted to frictional heat.

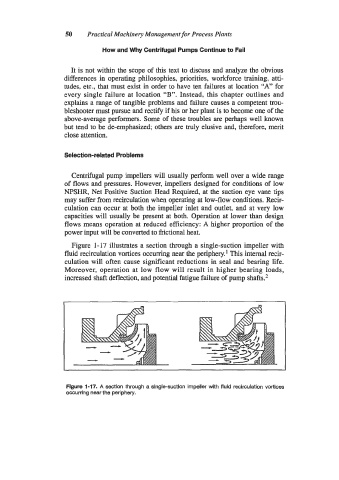

Figure 1-17 illustrates a section through a single-suction impeller with

fluid recirculation vortices occurring near the periphery. This internal recir-

culation will often cause significant reductions in seal and bearing life.

Moreover, operation at low flow will result in higher bearing loads,

increased shaft deflection, and potential fatigue failure of pump shafts.’

Figure 1-17. A section through a single-suction impeller with fluid recirculation vortices

xcurring near the periphery.