Page 67 - Practical Machinery Management for Process Plants Major Process Equipment Maintenance and Repair

P. 67

52 Practical Machinery Management for Process Plants

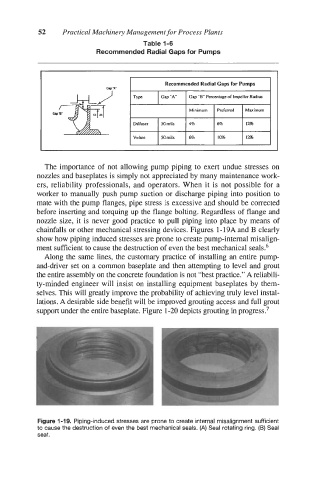

Table 1-6

Recommended Radial Gaps for Pumps

I

Recommended Radial Gaps for Pumps

10% 12%

The importance of not allowing pump piping to exert undue stresses on

nozzles and baseplates is simply not appreciated by many maintenance work-

ers, reliability professionals, and operators. When it is not possible for a

worker to manually push pump suction or discharge piping into position to

mate with the pump flanges, pipe stress is excessive and should be corrected

before inserting and torquing up the flange bolting. Regardless of flange and

nozzle size, it is never good practice to pull piping into place by means of

chainfalls or other mechanical stressing devices. Figures 1-19A and B clearly

show how piping induced stresses are prone to create pump-internal misalign-

ment sufficient to cause the destruction of even the best mechanical seals.6

Along the same lines, the customary practice of installing an entire pump-

and-driver set on a common baseplate and then attempting to level and grout

the entire assembly on the concrete foundation is not “best practice.” A reliabili-

ty-minded engineer will insist on installing equipment baseplates by them-

selves. This will greatly improve the probability of achieving truly level instal-

lations. A desirable side benefit will be improved grouting access and full grout

support under the entire baseplate. Figure 1-20 depicts grouting in progress.’

Figure 1-19. Piping-induced stresses are prone to create internal misalignment sufficient

to cause the destruction of even the best mechanical seals. (A) Seal rotating ring. (B) Seal

seat.