Page 434 - Practical Well Planning and Drilling Manual

P. 434

Section 3 revised 11/00/bc 1/17/01 12:00 PM Page 410

[ ] Practical Wellsite Operations

3.6.2

Rotary speed, RPM. Increasing RPM will increase ROP up to a

point where the cutters are moving too fast to penetrate the formation

before they move on. Excess RPM will cause premature bearing failure

or may cause PDC or diamond cutters to overheat.

Deviation is also affected by RPM. Higher rotary speeds tend to sta-

bilize the directional tendencies of rotary BHAs. A rotary BHA has a

natural tendency to turn to the right, this tendency is weaker at high-

er rotary speed.

Rotary speeds that cause string vibrations (critical rotary speeds)

must be avoided. The driller should recognize this condition and mod-

ify RPM accordingly. Two types of vibration can be related to drillstring

rotary speed and the calculated approximate speed of occurrence.

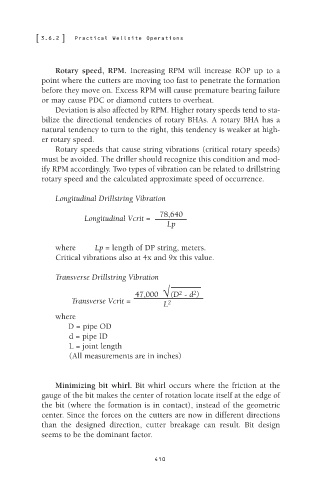

Longitudinal Drillstring Vibration

78,640

Longitudinal Vcrit =

Lp

where Lp = length of DP string, meters.

Critical vibrations also at 4x and 9x this value.

Transverse Drillstring Vibration

2

47,000 √(D - d )

2

Transverse Vcrit = L 2

where

D = pipe OD

d = pipe ID

L = joint length

(All measurements are in inches)

Minimizing bit whirl. Bit whirl occurs where the friction at the

gauge of the bit makes the center of rotation locate itself at the edge of

the bit (where the formation is in contact), instead of the geometric

center. Since the forces on the cutters are now in different directions

than the designed direction, cutter breakage can result. Bit design

seems to be the dominant factor.

410