Page 440 - Practical Well Planning and Drilling Manual

P. 440

Section 3 revised 11/00/bc 1/17/01 12:00 PM Page 416

[ ] Practical Wellsite Operations

3.6.6

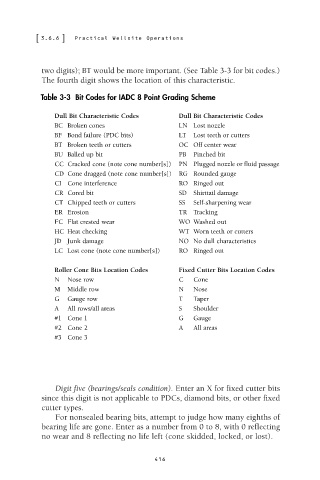

two digits); BT would be more important. (See Table 3-3 for bit codes.)

The fourth digit shows the location of this characteristic.

Table 3-3 Bit Codes for IADC 8 Point Grading Scheme

Dull Bit Characteristic Codes Dull Bit Characteristic Codes

BC Broken cones LN Lost nozzle

BF Bond failure (PDC bits) LT Lost teeth or cutters

BT Broken teeth or cutters OC Off center wear

BU Balled up bit PB Pinched bit

CC Cracked cone (note cone number[s]) PN Plugged nozzle or fluid passage

CD Cone dragged (note cone number[s]) RG Rounded gauge

CI Cone interference RO Ringed out

CR Cored bit SD Shirttail damage

CT Chipped teeth or cutters SS Self-sharpening wear

ER Erosion TR Tracking

FC Flat crested wear WO Washed out

HC Heat checking WT Worn teeth or cutters

JD Junk damage NO No dull characteristics

LC Lost cone (note cone number[s]) RO Ringed out

Roller Cone Bits Location Codes Fixed Cutter Bits Location Codes

N Nose row C Cone

M Middle row N Nose

G Gauge row T Taper

A All rows/all areas S Shoulder

#1 Cone 1 G Gauge

#2 Cone 2 A All areas

#3 Cone 3

Digit five (bearings/seals condition). Enter an X for fixed cutter bits

since this digit is not applicable to PDCs, diamond bits, or other fixed

cutter types.

For nonsealed bearing bits, attempt to judge how many eighths of

bearing life are gone. Enter as a number from 0 to 8, with 0 reflecting

no wear and 8 reflecting no life left (cone skidded, locked, or lost).

416