Page 442 - Practical Well Planning and Drilling Manual

P. 442

Section 3 revised 11/00/bc 1/17/01 12:00 PM Page 418

[ ] Practical Wellsite Operations

3.6.6

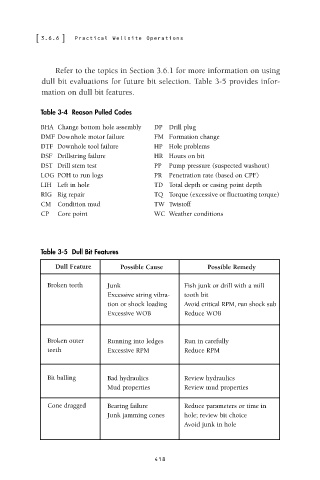

Refer to the topics in Section 3.6.1 for more information on using

dull bit evaluations for future bit selection. Table 3-5 provides infor-

mation on dull bit features.

Table 3-4 Reason Pulled Codes

BHA Change bottom hole assembly DP Drill plug

DMF Downhole motor failure FM Formation change

DTF Downhole tool failure HP Hole problems

DSF Drillstring failure HR Hours on bit

DST Drill stem test PP Pump pressure (suspected washout)

LOG POH to run logs PR Penetration rate (based on CPF)

LIH Left in hole TD Total depth or casing point depth

RIG Rig repair TQ Torque (excessive or fluctuating torque)

CM Condition mud TW Twistoff

CP Core point WC Weather conditions

Table 3-5 Dull Bit Features

Dull Feature Possible Cause Possible Remedy

Broken teeth Junk Fish junk or drill with a mill

Excessive string vibra- tooth bit

tion or shock loading Avoid critical RPM, run shock sub

Excessive WOB Reduce WOB

Broken outer Running into ledges Run in carefully

teeth Excessive RPM Reduce RPM

Bit balling Bad hydraulics Review hydraulics

Mud properties Review mud properties

Cone dragged Bearing failure Reduce parameters or time in

Junk jamming cones hole; review bit choice

Avoid junk in hole

418