Page 81 - Practical Well Planning and Drilling Manual

P. 81

Section 1 revised 11/00/bc 1/17/01 2:56 PM Page 57

1.4.7

Casing Design [ ]

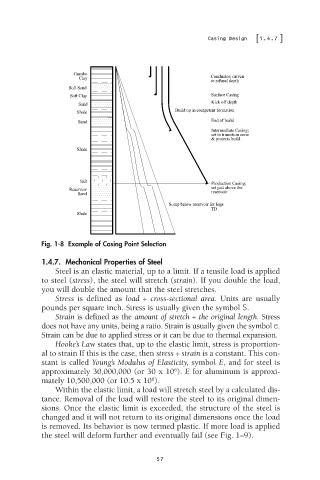

Gumbo

Clay Conductor; driven

to refusal depth

Soft Sand

Soft Clay Surface Casing

Sand Kick off depth

Build up in competent formation

Shale

Sand End of build

Intermediate Casing;

set in transition zone

& protects build

Shale

Salt

Production Casing;

Reservoir set just above the

Sand reservoir

Sump below reservoir for logs

TD

Shale

Fig. 1-8 Example of Casing Point Selection

1.4.7. Mechanical Properties of Steel

Steel is an elastic material, up to a limit. If a tensile load is applied

to steel (stress), the steel will stretch (strain). If you double the load,

you will double the amount that the steel stretches.

Stress is defined as load ÷ cross-sectional area. Units are usually

pounds per square inch. Stress is usually given the symbol S.

Strain is defined as the amount of stretch ÷ the original length. Stress

does not have any units, being a ratio. Strain is usually given the symbol e.

Strain can be due to applied stress or it can be due to thermal expansion.

Hooke’s Law states that, up to the elastic limit, stress is proportion-

al to strain If this is the case, then stress ÷ strain is a constant. This con-

stant is called Young’s Modulus of Elasticity, symbol E, and for steel is

6

approximately 30,000,000 (or 30 x 10 ). E for aluminum is approxi-

6

mately 10,500,000 (or 10.5 x 10 ).

Within the elastic limit, a load will stretch steel by a calculated dis-

tance. Removal of the load will restore the steel to its original dimen-

sions. Once the elastic limit is exceeded, the structure of the steel is

changed and it will not return to its original dimensions once the load

is removed. Its behavior is now termed plastic. If more load is applied

the steel will deform further and eventually fail (see Fig. 1–9).

57