Page 83 - Practical Well Planning and Drilling Manual

P. 83

Section 1 revised 11/00/bc 1/17/01 2:56 PM Page 59

Casing Design [ ]

1.4.7

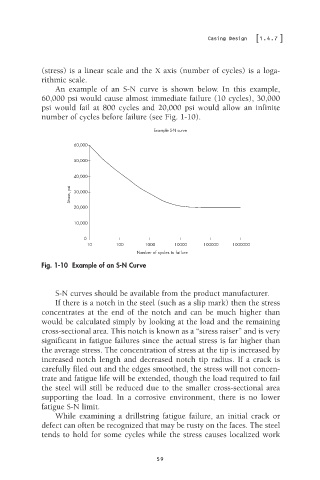

(stress) is a linear scale and the X axis (number of cycles) is a loga-

rithmic scale.

An example of an S-N curve is shown below. In this example,

60,000 psi would cause almost immediate failure (10 cycles), 30,000

psi would fail at 800 cycles and 20,000 psi would allow an infinite

number of cycles before failure (see Fig. 1-10).

Example S-N curve

60,000

50,000

40,000

Stress, psi 30,000

20,000

10,000

0

10 100 1000 10000 100000 1000000

Number of cycles to failure

Fig. 1-10 Example of an S-N Curve

S-N curves should be available from the product manufacturer.

If there is a notch in the steel (such as a slip mark) then the stress

concentrates at the end of the notch and can be much higher than

would be calculated simply by looking at the load and the remaining

cross-sectional area. This notch is known as a “stress raiser” and is very

significant in fatigue failures since the actual stress is far higher than

the average stress. The concentration of stress at the tip is increased by

increased notch length and decreased notch tip radius. If a crack is

carefully filed out and the edges smoothed, the stress will not concen-

trate and fatigue life will be extended, though the load required to fail

the steel will still be reduced due to the smaller cross-sectional area

supporting the load. In a corrosive environment, there is no lower

fatigue S-N limit.

While examining a drillstring fatigue failure, an initial crack or

defect can often be recognized that may be rusty on the faces. The steel

tends to hold for some cycles while the stress causes localized work

59