Page 180 - Pressure Vessel Design Manual

P. 180

158 Pressure Vessel Design Manual

Note: P.O.V. may be determined from chart in Figure 3-9. H

and D are in feet; t is in inches.

V = Ct,W, (from Procedure 3-3)

Ft = 0.07TV or 0.25V

whichever is less

Note: If H/D p 3 or T p 0.7 sec, then Ft = 0

Mi, = FtH + %(FH)

Moment at any height hi

Case 2: Nonuniform Vessels

Procedure €or finding period of vibration, moments,

and forces at various planes for nonuniform vessels.

A “nonuniform” vertical vessel is one that vanes in diameter,

thickness, or weight at different elevations. This procedure

distributes the seismic forces and thus base shear, along the

column in proportion to the weights of each section. The

results are a more accurate and realistic distribution of

forces and accordingly a more accurate period of vibration.

The procedure consists of two main steps:

V

Step 1: Determination of period of vibration (P.O.V.), T.

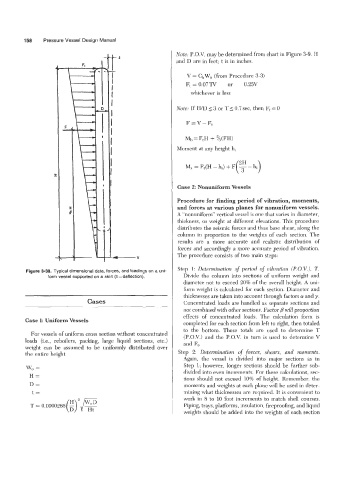

Figure 3-38. Typical dimensional data, forces, and loadings on a uni-

form vessel supported on a skirt (8 =deflection). Divide the column into sections of uniform weight and

diameter not to exceed 20% of the overall height. A uni-

form weight is calculated for each section. Diameter and

thicknesses are taken into account through factors a! and y.

Cases Concentrated loads are handled as separate sections and

not combined with other sections. Factor B will proportion

effects of concentrated loads. The calculation form is

Case 1: Uniform Vessels

completed for each section from left to right, then totaled

to the bottom. These totals are used to determine T

For vessels of uniform cross section without concentrated (P.O.V.) and the P.O.V. in turn is used to determine V

loads (i.e., reboilers, packing, large liquid sections, etc.) and F,.

weight can be assumed to be uniformly distributed over

the entire height. Step 2: Determination of forces, shears, and moments.

Again, the vessel is divided into major sections as in

W, = Step 1; however, longer sections should be further sub-

divided into even increments. For these calculations, sec-

H= tions should not exceed 10% of height. Remember, the

D= moments and weights at each plane will be used in deter-

mining what thicknesses are required. It is convenient to

t=

T = 0.0000265 (E) ‘Pg work in 8 to 10 foot increments to match shell courses.

--

Piping, trays, platforms, insulation, fireproofing, and liquid

weights should be added into the weights of each section