Page 261 - Pressure Vessel Design Manual

P. 261

Special Designs 239

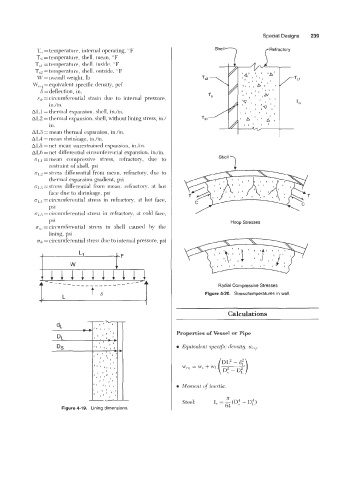

Shell7 Refractory

T,, = temperature, internal operating, O F

Ts =temperature, shell, mean, "F

Tbl =temperature, shell, inside, OF

TSz =temperature, shell, outside, OF

W = overall weight, Ib

W,.,, = equivalent specific density, pcf

8 =deflection, in.

E@ = circumferential strain due to internal pressure,

idin.

ALI =thermal expansion, shell, in./in.

AL2 = thermal expansion, shell, without lining stress, in./

in.

AL3 = mean thermal expansion, idin.

AL4 = mean shrinkage, in./in.

AL5 = net mean unrestrained expansion, idin.

ALli = net differential circumferential expansion, in./in.

n12, = mean compressive stress, refractory, due to Shell I

restraint of shell, psi

oL2 = stress differential from mean, refractory, due to

thermal expansion gradient, psi

=

n12,3 stress differential from mean, refractory, at hot

face due to shrinkage, psi

nL.$ = circumferential stress in refractory, at hot face,

psi

nL5 = circumferential stress in refractory, at cold face,

psi Hoop Stresses

n\<, = circumferential stress in shell caused by the

lining, psi

o,f, = circumferential stress due to internal pressure, psi

L1

W

I

11 11 11 1'1 11

---

---?

t-- ---______---- Radial Compressive Stresses

4

Figure 4-20. Stresdtemperatures in wall.

Calculations

Properties of Vessel or Pipe

0 Equicalent ,spec@ density, we,(/.

0 Moment of inertia.

Figure 4-19. Lining dimensions