Page 10 - Pressure Swing Adsorption

P. 10

viii

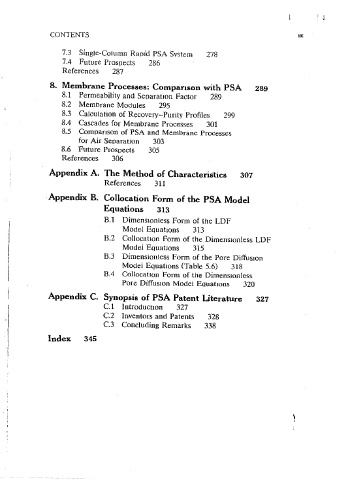

CONTENTS CONTENTS "'

3.3 Recovery of the More Strongly Adsorbed Species

7.3 Single-Column Raoid PSA Svstem 278

m Equilibnum-Controlled Separations 83

7.4 Future Prospects 286

3.4 Cycles for the Recove111 of Pure Raffinate Product

References 287

m Kinetically Controlled Seoarations 85

3.5 Cycle for Recovery of the Rapidly Diffusmg Species 93 8. Membrane Processes: Comparison with PSA 289

References 94

8.1 Permeability and Separation Factor 289

8.2 Membrane Modules 295

4. Equilibrium Theory of Pressure Swing Adsorption 95 8.3 Calculatton of Recovery-Punty Profiles 299

4.1 Background 95

8.4 Cascades for Membrane Processes 301

4.2 Mathematical Model 97

8.5 Comoanson of PSA and Membrane Processes

4.3 Model Parameters 102 for Air Seoaration 303

4.4 Cycle Analysis 105

8.6 Future Prospects 305

4.5 Exoerimental Validation 133 References 306

4.6 Model Companson 137

4.7 Design Example 143 Appendix A. The Method of Characteristics 307

4.8 Heat Effects 148 References 311

4.9 Pressunzat10n and B[owdown Steps 151

4.10 Conclus10ns 161 • Appendix B. Collocation Form of the PSA Model

References 163 Equations 313

B.1 Dimensionless Form of the LDF

5. Dynamic Modeling of a PSA System 165 Moctei Equations 313

5.1 Summary of the Dynamic Models 166 B.2 Colloca!Ion Form of the Dimensionless LDF

5.2 Details of Numencal Simulations 184 Modei Equations 315

5.3 Contmuous Countercurrent Models 201 B.3 Dimensionless Form of the Pore Diffusion

5.4 Heat Effects m PSA Systems 207 Model Equations (Table 5.6) 318

References 217 B.4 Collocat1~n Form of the Dimensionless

Pore Diffusion Model Eouatmns 320

6. PSA Processes 221

6. 1 Air Drymg 221 Appendix C. Synopsis of PSA Patent Literature 327

6.2 Production of Oxygen 226 C. l lntroductton 327

C.2 Inventors and Patents 328

6.3 Production of Nitrogen 230

C.3 Concluding Remarks 338

6.4 PSA Process for Simultaneous Production of 0 and N 232

6.5 Hydrogen Recovery 235 2 2 Index 345

6.6 Recovery of CO 242

2

6.7 Recove111 of Methane from Landfill Gases 244

6.8 Hydrocarbon Separations 246

6. 9 Process for Simultaneous Production of H and CO

2 2

from Reformer Off-Gas 246

6.10 PSA Process for Concentratmg a Trace Component 251

6.11 Efficiency of PSA Processes 258

References 263

7. Extensions of the PSA Concept 265

7.1 The Pressure Swmg Parametnc Pump 265

7 .2 Thermally Coupled PSA 270