Page 246 - Pressure Swing Adsorption

P. 246

I

222 PRESSURE SWING ADSORPTION PSA PROCESSES 223

The equilibnum isotherm for water vapor on alumma 1s less strongly 6.1.2 Bed Diameter

curved than the corresponding isotherm for zeolite adsorbents (see Figure

2.5) and as a result, the working capacity m a PSA system 1s higher. However, The bed diameter is chosen m the normal way basect on the design through-

a more important considerat10n 1s that aiumma beads are physically more put reqmrement. The maximum velocity m upflow 1s normally limited to 75%

robust than most other cles1ccants and do not fracture or suffer attrition of the m1mmum fluidizatton velocity to avoid the increased attnt1on resuiting

under the rather harsh operating conditions of a PSA process. Indeed, from oarticie vibrat10n, which becomes serious. even m-a well oacked bed, as

provided that the feed air is clean, the life of a PSA drier packed with the fluidizatlon velocity is approached. A somewhat higher veioc1ty, oerhaps

alumma beads is very long; continuous ooeratwn without changing the double the fluidizat1on velocity, can be toierated m downflow.::

adsorbent over a penod of 20 years has been reported.

6.1.3 Bed Length

6.1.1 Design Considerations

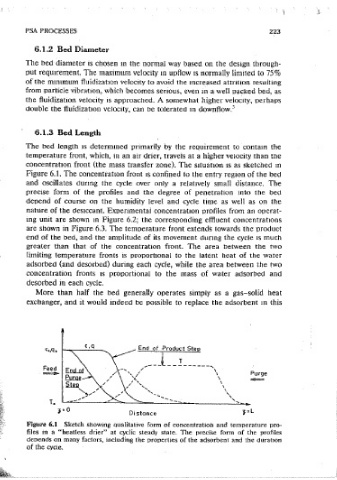

The bed iength 1s detennmed pnmarily by the requirement to contam the

Product punty is normally the pnmary reomrement and, smce the water temperature front, which, m an air drier, travels at a higher velocity than the

vapor concentration m the feed is generally quite low, a pressure eaualization concentration front (the mass transfer zone). The s1tuat1on 1s as sketched m

step 1s not normally included in the cycle. Mimm1zat1on of the purge, subject Figure 6.1. The concentratton front is confined to the entry region of the bed

to the reqmrement of a pure oroduct, 1s therefore the maJor objective in and oscillates dunng the cycle over only a relatively small distance. The

ootlmization of the operatmg cycle. The process operates under essentially precise form of the profiles and the degree of penetration into the bed

adiabatic conditions, and conservation of the heat of adsorotlon 1s therefore depend of course on the humidity level and cycle time as well as on the

a major consideration determining the selectmn of operating conditions. In nature of the desiccant. Exoenrnentai concentrat10n orofiles from an operat-

essence the desiccant bed must be sufficiently tong that, during the adsorp~ ing unit are shown m Figure 6.2; the corresponding effluent concentrations

t1on step, the thermal wave (which travels faster than the mass transfer zone) are shown in Figure 6.3. The temperature front extends towards the product

does not escape from the bed. The heat retained in the bed heats the purge end of the bed, and the amplitude of its movement dunng the cycle 1s much

gas dunng the desorption step, thus reducing the volume of purge reqmred greater than that of the concentration front. The area between the two

to desorb the water. If the bed is too short so that the thermal front 1s not limiting temperature fronts is proportional to the latent heat of the water

contamed, some of the heat will be iost (as sensible heat m the product adsorbed (and desorbed) during each cycie, while the area between the two

stream). Under these conditions a greater volume of purge will be needed to concentration fronts 1s proportional to the mass of water adsorbed and

clean the bed with consequent loss of process efficiency. desorbed m each cycle.

Skarstrom enunciated three general principles for the design of a "heat- More than half the bed generally operates simply as a gas-solid heat

less drier" exchanger, and it would indeed be possible to replace the adsorbent m this

1. Conservation of the heat of adsorot1on (as discussed). This reamres

relat1veiy short cycles with low throughput per cycle.

2. Regeneration at low pressure using a fraction of the product stream as a

reverse-flow purge. In order to produce a oure product the actual purge c,q

volume should exceed the actual feed volume at all points in the bed. c.,q.

3. For a pure Product the absoiute pressure ratio (PH/PL)"should be greater

than the reciprocal of the mole ratio of the oroctuct to the feed. --- Purge

Feed

It is dear that, under cyclic steady-state conditiorts, all water vaoor <=

enteting with the feed must be removed in the purge (~part from the small

Joss m the blowdown). The maximum water vapor content of the purge gas T.

will be the same as that of the high,..pressure feed. Cyclic steady-state pO

operation is therefore only possible with a volumetric purge~to-feed ratio Distance

greater than unity. The third orincipie also follows directly from the overall Figure 6-.1 Sketch showmg Qualitative form of concentration and temperaiUre pro-

files m a "heatless drier" at cyclic steady state. The precise form of the profiles

mass balance. A useful summary of the procedure that 1s normally followed depends on many factors, including the properties of the adsorbent and the durat10n

m the design of a PSA dner has been given by White. 2 of the cycJe.