Page 250 - Pressure Swing Adsorption

P. 250

,. ,·

226 PRESSURE SWING ADSORPTION PSA PROCESSES 227

10

rangmg from a few liters per minute, for medical oxygeln, to tens of tons per

8

i 4-1/2" day for industrial systems. A zeolite adsorbent, generally SA or IJX. IS

u •

;: normally used. When thoroughly dehydrated, such adsorbents show a selec-

" t1v1ty towards mtrogen with a separat10n factor of about 3.0-3.5. Oxygen

6

0

0 « 4

._ and argon are adsorbed with almost the same affimty; so the separation is m

,!a effect between oxygen plus argon and rntrogCn. The maximum attainfihle

0 oxygen punty is therefore about 95-96%. The oresence of argon as an

N

X 2

._ nnounty 1s of little consequence for medical purposes, :but It 1s a significant

~

._ disadvantage for welding and cutting, smce the flame temperature, and

'

0

w therefofe the cuttmg soeed, arc significantly reduced .. Substantially higher

... l seoarat10n factors (aN 2102 ~ 8-10, with corresoondingly higher ·mtrogenca-

w

"' 0.8 oacity) have been reported for thoroughly dehydrated CaX and, vanous 1omc

0

N 7 8 The Henry constant for nitrogen on these "second

~ 0.6 forms of chabazite. ·

~ generation" adsorbents 1s too high to permit effective desorptmn at atmo-

._

e,

0.4 spheric pressure, making them unsuitable for use m a conventional PSA cycle

0

~ ooeratmg at pressures above atmospheric. These adso'fbents are. however,

"

<>

J used m many of the more modern large-scale vacuum swmg or

SA SIEVES

0.2 l/16" PELLETS pressure /vacuum swmg processes. The development of these processes pro-

vides an excellent example of the need to tailor the process cycle to the

properties of the adsorbent.

O., '----...l~'....J.-..i.-...LJ....Ll.J.JL---...L-..1..-L-J._J....l.J..W

o.' 0.2 0.4 O,b l.O 2.0 4.0 t,,O 10

ACTUAL VOLUMES PER CYCLE: PURG£/FEEO 6.2, l Small-Scale Medical Oxygen Umts

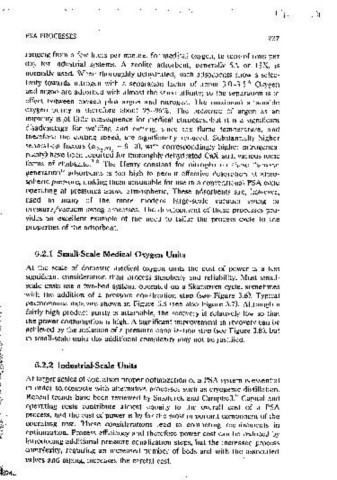

Figure 6.4 Effect of ourge-to-feed ratio on product purity for a "heatless dner" At the scale of domestic medical oxygen units the cost of power is a less

packed with 5A zeolite. Feed 26 SCFI-1 at 80° F, 4.7 atm, _6000 ppm H 0. (From significant considerat10n than process s1molic1ty and reliability. Most small-

2

5

Skarstrorn, with oetmissmn.)

scale units use a two-bed system, operated on a Skarstrom cycle, sometimes

with the addition of a pressure equalization step (see Figure 3.6). Typical

6.1.5 Product Purity performance data are shown in Figure 6.5 (see also Figure 3.7). Although a

fairiy high product purity 1s attamable, the recovery is relatively low so that

The product pu'rity ts determined by the bed length (or the dimensionless the power consumption 1s high. A significant mmrovement 1n recovery can be

ratio L/vt,) and the ourge-to-feed ratio. Experimental results obtained with achieved by tlle mciusion of a pressure equalization step (see Figure 3.8). but

a coiumn of SA sieve of different lengths at various·purge•to-feed ratios are in small-scale units the additional complexity may not be Justified.

summanzed m Figure 6.4. The asymotot1c line 1s s1moiy calculated from the

mass balance:

c, F - (PL/P . )P 6.2.2 .Industrial-Scale Units

_.:;_ = 11 (6.2)

cP F-P

At larger scales of ooerat1on orooer ootimization of a PSA system 1s essential

With adeauate ourge and adequate bed length the oroduct air IS essentially in order to. compete with alternative orocesses such as cryogernc distillation.

9

bone dry. If the purge is msuffic1ent or if the bed length ,s not long enough to Recent trends have been reviewed by Smolarek and Campbel'l. Capita! and

contain the temperature wave, the performance deteriorates. operating costs contribute almost eaually to the overall cost of a PSA

process, and the cost of power 1s by far the most 1moortant component of the

operating cost. These consideratwns lead to competing reauirements in

6.2 Production of Oxygen optimization. Process efficiency and therefore power cost can be reduced by

introducmg additional oressure eaualization steps, but the increased process

Air separation to produce oxygen was one of the processes described in the comolexity, reqmring an increased number of beds and with the associated

5

early PSA patents of Skarstrom. It has been commerctalized at scales valves and oioing, increases the cao,tal cost.