Page 284 - Pressure Swing Adsorption

P. 284

PRESSURE SWING ADSORPTION PSA PROCESSES 261

260

of expans10n of the product to atmospheric pressure. For a vacuum swi?g without pressure equalization there 1s a shallow rnm11num m the comoressor

process· m which the product 1s produced at subatmosphenc pr~ssure, the \ work curve at about 15 atm; while for the process with pressure equalization

latter quantity will be negative. Eauation 6.15 differs from the normal the compressor work 1s greatly reduced and there is a sharoer minimum at

definition of the First Law efficiency in that the seoarattve work associated l about 4 atm. The exerget1c efficiency reaches a maximum at aoout 5 atm for

with the waste product 1s excluded and the energy of compress10n (or I the process with pressure eQualization but increases monotomcally for the

rations were considered: the two-bed Skarstrom cycle with and without _a I grams for operation at their ootimal pressures (in terms of compressor work)

expansion) of the product to atmosohenc pressure is allowed for. process without oressure equalization. The correspdnding Grassman dia-

-A detailed exergy analysis of PSA air separation processes has been

are shown in Figure 6.26. The exerget1c efficiency is about 17% for the

40 41

For oxygen production tw? process ~onfigu-

reported by B·anerjee et al.

,

pressure equalization step. The variation of compressor work and exerget!c

efficiency with operating pressure 1s shown in Figure 6.25. For the cycle COtfflGURATlON

EXERGY

OF

WO«K lam

INPUT FEED

'• (a) 10•" I

(100¼)

PAOOl)Cl

OHGE~ 1014\

1)1J<] w, t~•J•.1

1100•1,1

l)OOO U•$'lol

••T~~c~l•O

sOSHS U\U C0NFIGURAI10N 1 EXO 0-0t (0.5°/o)

""·~•,.)

EX ERG¥

WORK OF

INPUT FEED

IHG 6•1J ( 70¼)

(a)

1100"/ol

(b)

t'wJTV

0,31 I l·6"/,)

COMPRES

f.XIT

7113

SlREAM rsc'-"=~, 111•1•,.,

)!178& 3•56

161"/ol ly 1-76150"/.J

y,:__.,~;.__E:X9 :0-0411•1"/ol

(c) O 0·01(0•3•1.1

AFTERCOOlER

l05S •lO ll•B'Vo) 0•1514•2•/•l

COMPRESSOR 8657 FEED

tOSSES I 21•5 •/•l EXERGY .. 0

53.!9

tu.,,.1 -0-09

i-2-s.,-. J

(b)

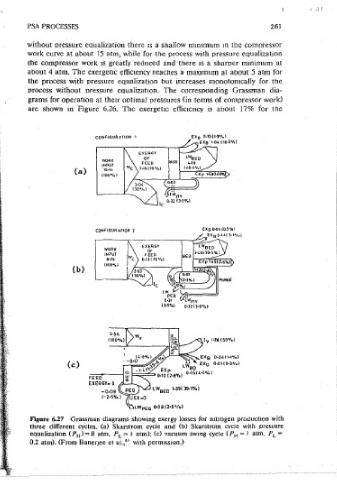

Figure 6.26, Grassman diagrams showmg losses of exergy for S~arstrom ~de (blo:,v-

down to atmosohenc pressure) for oxygen production (a) without .and ~b) with Figure 6.27 Grassman diagrams showing exergy losses for mtrogen production with

three different cycles. (a) Skarstrom cycle and (b) SkarstrO:m cvcJe with pressure

pressure eoualization. Ooeratmg pressures are, ,resoect1vely, 15.b and 3.9. b~r, t.he

Va1ues for Which the compressor work 1s m1mm1zed. (From Banenee et al., with equalization (PH)= 8 atm, PL= 1 atm); {c) vacuum swing cycle (PH= 1 atm, Pi.=

0.2 atm). (From Banef]ee et ai., 41 with pcrm1ss1on.)

perm1ss1on.)