Page 294 - Pressure Swing Adsorption

P. 294

I I

270 PRESSURE SWING ADSORPTION

EXTENSIONS OF THE PSA CONCEPT

271

these sm1Ple arguments; ootirnai performance is obtamed when the phase

angle difference is about 45° and the ratio of the piston strokes ts about 3.5:1. \

As a separation process the pressure swmg oarametnc pump has two

maJor advantages:

I. It can produce two oure products; so complete resolution of a hinary

hot space

nuxture may lie achieved without the complexity of the purge and nnse (wod~ing gas 1s

steps that are reauirect to accomplish this in the normai PSA mode (sec / found in here

while it expands)

Sect10n 6.3).

2. The system can be easily designed to provide efficient energy recovery, ,-regenerator

since, on the -exoans1on stroke, the 01stons are dnven by the pressure of

the gas. Conseivation of this energy for use in the next compression stroke displacer ~cooler

c3n be easily accomolished either usmg a flywheel or by coupling together

two umts operatmg-out of phase.

There 1s, however, one serious disadvantage: the pistons and cylinders

must be large enough to accommodate virtually all the gas desorbed from the cold space

bed at the lowest pressure of the cycle. For a bench-scale umt this 1s not a (working gas 1s

~ found in here

serious problem, but it does present a serious obstacle to scaleup. when compressed)

I

7 .2 Thermally Coupled PSA

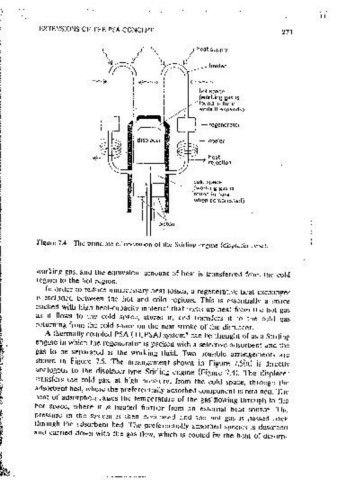

In the previous section we considered the molecular gate as a oressure-driven l Figure 7.4 The pnnc1ple of operation of the Stiriing engme (dispiacer type).

oarametnc oumo. This system is also closely related to the Stirling engine

and thus to a nOvei class of processes that utilize oenodic vanatiOns in both

pressure and temperature together with an oscillating gas flow to effect an working gas, and the eqmvaient amount of heat is transferred from the cold

energetically efficient separation. The basic elements of a Stirling engme are region to the hot region.

shown in Figure 7.4. As in the molecular gate there are two 01stons: a In order to reduce unnecessary heat losses, a regenerative heat exchanger

pressure piston and a displacer, in an arrangement that ts similar tn essence IS mclucted between the hot and cold regions. This is essentially a soace

to that shewn in Figure 7 .2. The working gas 1s transferred backWarcts and

oackect with high-heat-capacity matenal that 01cks up heat from the hot gas

forward between the ''hot space" and the "cold space" by the displacer

as It flows to the cold space, stores 1t. and transfers it to the cold gas

otston. There is very littie difference in pressure between the hot and cold

returning from the cold space on the next stroke of the displacer.

~paces: so the disoiacer does very little mechamcal work. However, the A thermally coupled PSA (TCPSA) system can be thought of as a Stirling

4

Pressure throughOll~ the system varies sinusoidally as a result of the move- engme in which the regenerator 1s packed with a selective adsorbent and the

ment of the pressure piston. When 'the system operates as an engme, gas

gas to be separated 1s the working fluid. Two possible arrangements are

expands m the hot space and flows mto the cold space, ctnvmg down the

shown m Figure 7.5. The arrangement shown m Figure 7.5(a) is directly

pressure mston. The displacer then moves down, transfernng the cold gas at

analogous to the displacer-type Stiriing engme (Figure 7.4). The disoiacer

low pressure back to the hot space. The pressure piston is then raised,

transfers the cold gas, at high pressure, from the cold space. through the

mcreasing the pressure m the system, while the gas m the ·hot space ts

adsorbent bed, where the preferentially adsorbed component 1s retained. The

heated, causmg a further nse m pressure, and the cycle is repeated. In this heat of adsorption raises the temperature of the gas flowing through to the

mode of operation the net effect is that heat 1s transferred by the gas from

hot spa·ce, where Jt 1s heated further from an external heat source. The

the hot to -cold regions and an eqUivalent amount of work is delivered to the pressure in the system 1s then decreased and the hot g11s 1s passed back

pressure piston. The system can also he operated in reverse as a heat pumo through the adsorbent bed. The prcfcrcnt1a/ly adsorbed species is dcsorhed

or refrigeratm;. In that mode, work 1s dOne by the pressure piston on the

and earned down with the gas tlow, which 1s cooled by the heat of desorp-