Page 295 - Pressure Swing Adsorption

P. 295

ii I.

272 PRESSURE SWING ADSORPTION

EXTENSIONS OF THE PSA CONCEPT

273

Compression

ADSORBENT

REGENERATOR

High pressure

flow

DISPLACER

PISTON

COLD

Expons1on

Low pressure

How

MORE ADSORBED \ FEED GAS

PRODUCT MIXTURE

FRACTION

LESS ADSORBED

PRODUCT

FRACTION

(a)

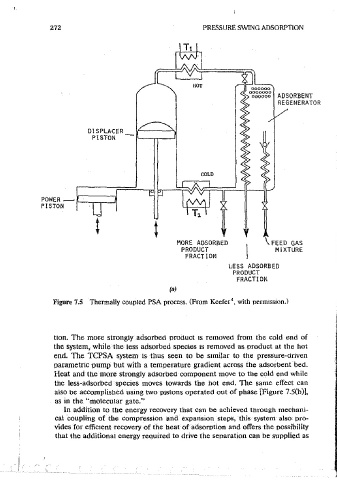

Pigure 7.5 Thermally coupled PSA process. (From Keefer\ with permission.) Net. result. Heol

Mor• odt<>rb•d ----~---

lroctlon L•o Od1orb4,d

Tl TZ lroct1on

(b)

tion. The more strongly adsorbed product 1s removed from the cold end of Figure 7.5 (ConJinued).

the system,. while the less adsorbed species 1s removed as product at the hot

end. The TCPSA system is thus seen to be similar to the pressure-ctriven heat rather than as m h .

1

parametric -pump but with a temperature gradient across the adsorbent bed. energy-effi - t ec amca energy. This Provides- the Potential for an

c1en and _cost-effective system powered by relatively low- rade

Heat and the more strongly adsorbed. component move to the cold end while

wast~d heat. The apphcat10n of a process of this kind to a reactmg syst!m to

the less-adsorbed species moves towards the hot end. The same effect can

:::v10; thcoenTt,CnuPoSuAs separation of the react10n products is an obVious exten-

also be accomplished using two 01stons operated out of phase [Figure 7.S(b)],

conceot.

as in the. ''molecular gate."

In addition to tt1e energy recovery that can be achieved through mechani-

7 ,2.1 Test Results

cal coupling of the compression and expansion steps, this system· also pro-

vides for efficient recovery of the heat of adsorption and offers the possibility Experimental data obta - d f h d .

that the additional energy required to drive the seoaration can be supplied as Ptoctuce oxygen) in a me II o: Y rogen ounficat1on arid air separation (to

sma laboratory TCPSA unit are summarized m

I