Page 91 - Primer on Enhanced Oil Recovery

P. 91

82 Primer on Enhanced Oil Recovery

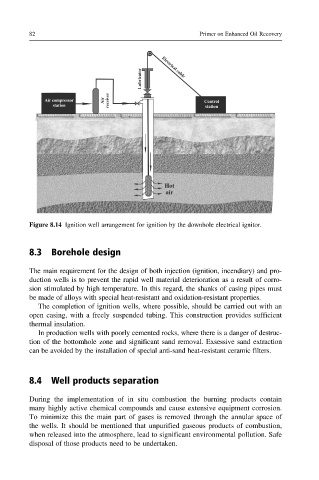

Figure 8.14 Ignition well arrangement for ignition by the downhole electrical ignitor.

8.3 Borehole design

The main requirement for the design of both injection (ignition, incendiary) and pro-

duction wells is to prevent the rapid well material deterioration as a result of corro-

sion stimulated by high temperature. In this regard, the shanks of casing pipes must

be made of alloys with special heat-resistant and oxidation-resistant properties.

The completion of ignition wells, where possible, should be carried out with an

open casing, with a freely suspended tubing. This construction provides sufficient

thermal insulation.

In production wells with poorly cemented rocks, where there is a danger of destruc-

tion of the bottomhole zone and significant sand removal. Exsessive sand extraction

can be avoided by the installation of special anti-sand heat-resistant ceramic filters.

8.4 Well products separation

During the implementation of in situ combustion the burning products contain

many highly active chemical compounds and cause extensive equipment corrosion.

To minimize this the main part of gases is removed through the annular space of

the wells. It should be mentioned that unpurified gaseous products of combustion,

when released into the atmosphere, lead to significant environmental pollution. Safe

disposal of those products need to be undertaken.