Page 87 - Primer on Enhanced Oil Recovery

P. 87

78 Primer on Enhanced Oil Recovery

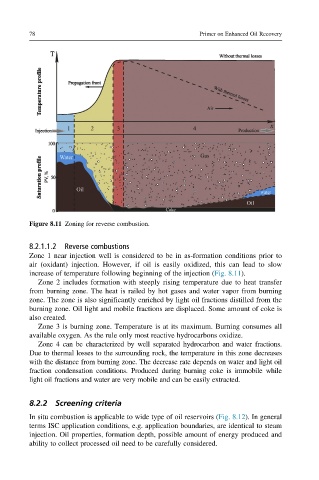

Figure 8.11 Zoning for reverse combustion.

8.2.1.1.2 Reverse combustions

Zone 1 near injection well is considered to be in as-formation conditions prior to

air (oxidant) injection. However, if oil is easily oxidized, this can lead to slow

increase of temperature following beginning of the injection (Fig. 8.11).

Zone 2 includes formation with steeply rising temperature due to heat transfer

from burning zone. The heat is railed by hot gases and water vapor from burning

zone. The zone is also significantly enriched by light oil fractions distilled from the

burning zone. Oil light and mobile fractions are displaced. Some amount of coke is

also created.

Zone 3 is burning zone. Temperature is at its maximum. Burning consumes all

available oxygen. As the rule only most reactive hydrocarbons oxidize.

Zone 4 can be characterized by well separated hydrocarbon and water fractions.

Due to thermal losses to the surrounding rock, the temperature in this zone decreases

with the distance from burning zone. The decrease rate depends on water and light oil

fraction condensation conditions. Produced during burning coke is immobile while

light oil fractions and water are very mobile and can be easily extracted.

8.2.2 Screening criteria

In situ combustion is applicable to wide type of oil reservoirs (Fig. 8.12). In general

terms ISC application conditions, e.g. application boundaries, are identical to steam

injection. Oil properties, formation depth, possible amount of energy produced and

ability to collect processed oil need to be carefully considered.