Page 84 - Primer on Enhanced Oil Recovery

P. 84

Thermal EOR 75

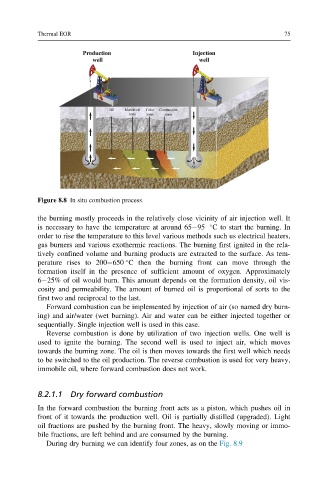

Figure 8.8 In situ combustion process.

the burning mostly proceeds in the relatively close vicinity of air injection well. It

is necessary to have the temperature at around 65 95 C to start the burning. In

order to rise the temperature to this level various methods such us electrical heaters,

gas burners and various exothermic reactions. The burning first ignited in the rela-

tively confined volume and burning products are extracted to the surface. As tem-

perature rises to 200 650 C then the burning front can move through the

formation itself in the presence of sufficient amount of oxygen. Approximately

6 25% of oil would burn. This amount depends on the formation density, oil vis-

cosity and permeability. The amount of burned oil is proportional of sorts to the

first two and reciprocal to the last.

Forward combustion can be implemented by injection of air (so named dry burn-

ing) and air/water (wet burning). Air and water can be either injected together or

sequentially. Single injection well is used in this case.

Reverse combustion is done by utilization of two injection wells. One well is

used to ignite the burning. The second well is used to inject air, which moves

towards the burning zone. The oil is then moves towards the first well which needs

to be switched to the oil production. The reverse combustion is used for very heavy,

immobile oil, where forward combustion does not work.

8.2.1.1 Dry forward combustion

In the forward combustion the burning front acts as a piston, which pushes oil in

front of it towards the production well. Oil is partially distilled (upgraded). Light

oil fractions are pushed by the burning front. The heavy, slowly moving or immo-

bile fractions, are left behind and are consumed by the burning.

During dry burning we can identify four zones, as on the Fig. 8.9