Page 82 - Primer on Enhanced Oil Recovery

P. 82

Thermal EOR 73

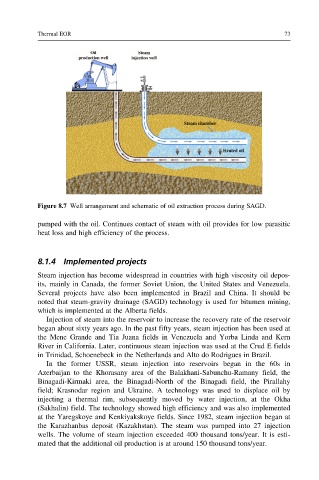

Figure 8.7 Well arrangement and schematic of oil extraction process during SAGD.

pumped with the oil. Continues contact of steam with oil provides for low parasitic

heat loss and high efficiency of the process.

8.1.4 Implemented projects

Steam injection has become widespread in countries with high viscosity oil depos-

its, mainly in Canada, the former Soviet Union, the United States and Venezuela.

Several projects have also been implemented in Brazil and China. It should be

noted that steam-gravity drainage (SAGD) technology is used for bitumen mining,

which is implemented at the Alberta fields.

Injection of steam into the reservoir to increase the recovery rate of the reservoir

began about sixty years ago. In the past fifty years, steam injection has been used at

the Mene Grande and Tia Juana fields in Venezuela and Yorba Linda and Kern

River in California. Later, continuous steam injection was used at the Crud E fields

in Trinidad, Schoenebeck in the Netherlands and Alto do Rodrigues in Brazil.

In the former USSR, steam injection into reservoirs began in the 60s in

Azerbaijan to the Khorasany area of the Balakhani-Sabunchu-Ramany field, the

Binagadi-Kirmaki area, the Binagadi-North of the Binagadi field, the Pirallahy

field; Krasnodar region and Ukraine. A technology was used to displace oil by

injecting a thermal rim, subsequently moved by water injection, at the Okha

(Sakhalin) field. The technology showed high efficiency and was also implemented

at the Yaregskoye and Kenkiyakskoye fields. Since 1982, steam injection began at

the Karazhanbas deposit (Kazakhstan). The steam was pumped into 27 injection

wells. The volume of steam injection exceeded 400 thousand tons/year. It is esti-

mated that the additional oil production is at around 150 thousand tons/year.