Page 291 - Process Equipment and Plant Design Principles and Practices by Subhabrata Ray Gargi Das

P. 291

11.4 Fractionator 293

Hat

Vapour

Chimney

Draw off

Chimney

tray pan

Vapour

Column Side draw

shell

nozzle

Internal reflux

to lower tray

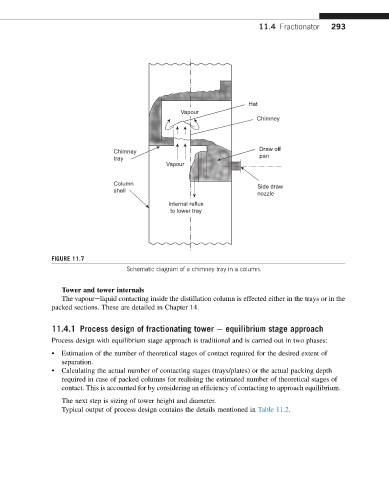

FIGURE 11.7

Schematic diagram of a chimney tray in a column.

Tower and tower internals

The vapoureliquid contacting inside the distillation column is effected either in the trays or in the

packed sections. These are detailed in Chapter 14.

11.4.1 Process design of fractionating tower e equilibrium stage approach

Process design with equilibrium stage approach is traditional and is carried out in two phases:

• Estimation of the number of theoretical stages of contact required for the desired extent of

separation.

• Calculating the actual number of contacting stages (trays/plates) or the actual packing depth

required in case of packed columns for realising the estimated number of theoretical stages of

contact. This is accounted for by considering an efficiency of contacting to approach equilibrium.

The next step is sizing of tower height and diameter.

Typical output of process design contains the details mentioned in Table 11.2.