Page 318 - Process Equipment and Plant Design Principles and Practices by Subhabrata Ray Gargi Das

P. 318

320 Chapter 11 Distillation

The number of trays is close to what was assumed and hence the column pressure drop is

reasonably assumed. Also the relative volatility estimation is ok.

Column diameter and internals are to be designed based on the content of Chapter 14.

11.6 Flash distillation

The process of flash distillation has been introduced right at the beginning of this chapter. This can also

be seen as a process of fractionation with a single stage. Since there is only one stage of contact, the

purpose of the fractionator column is served by a simple vessel called the flash drum. The feed can be

liquid or a mixture of vapour and liquid. Heat may be added, if necessary, to the system in a feed

preheat exchanger. In some cases a heating coil or jacket integral with the flash drum is used for adding

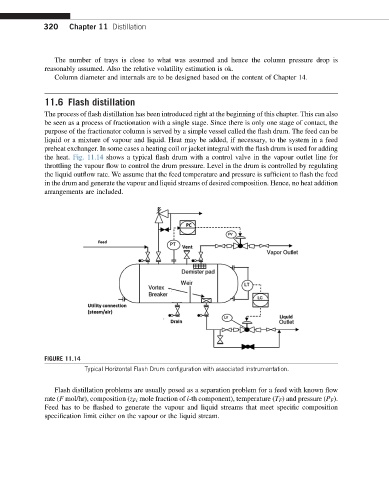

the heat. Fig. 11.14 shows a typical flash drum with a control valve in the vapour outlet line for

throttling the vapour flow to control the drum pressure. Level in the drum is controlled by regulating

the liquid outflow rate. We assume that the feed temperature and pressure is sufficient to flash the feed

in the drum and generate the vapour and liquid streams of desired composition. Hence, no heat addition

arrangements are included.

FIGURE 11.14

Typical Horizontal Flash Drum configuration with associated instrumentation.

Flash distillation problems are usually posed as a separation problem for a feed with known flow

rate (F mol/hr), composition (z Fi mole fraction of i-th component), temperature (T F ) and pressure (P F ).

Feed has to be flashed to generate the vapour and liquid streams that meet specific composition

specification limit either on the vapour or the liquid stream.