Page 332 - Process Equipment and Plant Design Principles and Practices by Subhabrata Ray Gargi Das

P. 332

334 Chapter 11 Distillation

(A) Cooling Cooling

water in water out

Condenser

EQUALISER line

to condenser

shell Reflex (B) Condenser

line

Cooling Water

3-way valve to

control reflux

Distillate

Tray

column

Distillate Vapour Packed

column

Steam

Condensate Reboiler

Change

still Liquid Bottoms

Steam

Bottoms

Condensate

FIGURE 11.18

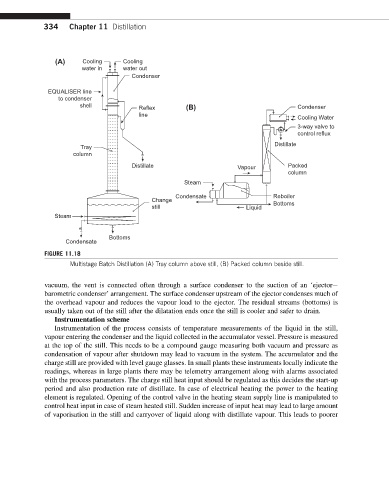

Multistage Batch Distillation (A) Tray column above still, (B) Packed column beside still.

vacuum, the vent is connected often through a surface condenser to the suction of an ‘ejectore

barometric condenser’ arrangement. The surface condenser upstream of the ejector condenses much of

the overhead vapour and reduces the vapour load to the ejector. The residual streams (bottoms) is

usually taken out of the still after the dilatation ends once the still is cooler and safer to drain.

Instrumentation scheme

Instrumentation of the process consists of temperature measurements of the liquid in the still,

vapour entering the condenser and the liquid collected in the accumulator vessel. Pressure is measured

at the top of the still. This needs to be a compound gauge measuring both vacuum and pressure as

condensation of vapour after shutdown may lead to vacuum in the system. The accumulator and the

charge still are provided with level gauge glasses. In small plants these instruments locally indicate the

readings, whereas in large plants there may be telemetry arrangement along with alarms associated

with the process parameters. The charge still heat input should be regulated as this decides the start-up

period and also production rate of distillate. In case of electrical heating the power to the heating

element is regulated. Opening of the control valve in the heating steam supply line is manipulated to

control heat input in case of steam heated still. Sudden increase of input heat may lead to large amount

of vaporisation in the still and carryover of liquid along with distillate vapour. This leads to poorer