Page 122 - Reciprocating Compressors Operation Maintenance

P. 122

Operation and Maintenance of Reciprocating Compressors 1 O9

necting rods dips into the oil and produces a spray that reaches all inter-

nal parts.

Where the splash method is employed, the level of oil in the reservoir

should be maintained within predetermined limits in order to prevent

either over or under lubrication.

Splash and Flood Lubrication

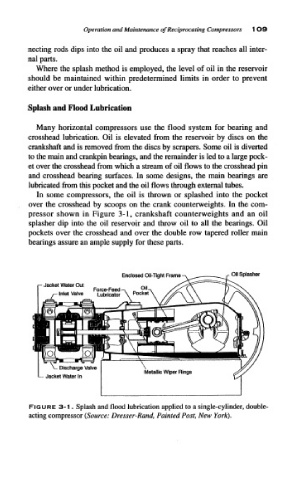

Many horizontal compressors use the flood system for bearing and

crosshead lubrication. Oil is elevated from the reservoir by discs on the

crankshaft and is removed from the discs by scrapers. Some oil is diverted

to the main and crankpin bearings, and the remainder is led to a large pock-

et over the crosshead from which a stream of oil flows to the crosshead pin

and crosshead bearing surfaces. In some designs, the main bearings are

lubricated from this pocket and the oil flows through external tubes.

In some compressors, the oil is thrown or splashed into the pocket

over the crosshead by scoops on the crank counterweights. In the com-

pressor shown in Figure 3-1, crankshaft counterweights and an oil

splasher dip into the oil reservoir and throw oil to all the bearings. Oil

pockets over the crosshead and over the double row tapered roller main

bearings assure an ample supply for these parts.

Enclosed Oil-Tight Frame -^ __—-— r Oil Splasher

V. Discharge Valve

Metallic Wiper Rings s?

Jacket Water In

^

FIGURE 3-1. Splash and flood lubrication applied to a single-cylinder, double-

acting compressor (Source: Dresser-Rand, Painted Post, New York),