Page 123 - Reciprocating Compressors Operation Maintenance

P. 123

1 1 O Reciprocating Compressors: Operation and Maintenance

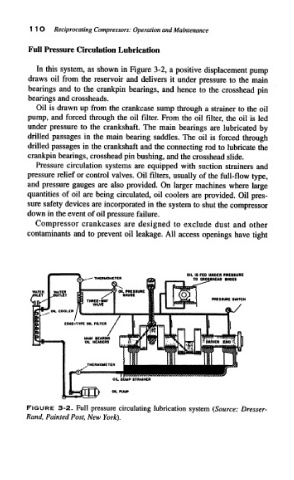

Full Pressure Circulation Lubrication

In this system, as shown in Figure 3-2, a positive displacement pump

draws oil from the reservoir and delivers it under pressure to the main

bearings and to the crankpin bearings, and hence to the crosshead pin

bearings and crossheads.

Oil is drawn up from the crankcase sump through a strainer to the oil

pump, and forced through the oil filter. From the oil filter, the oil is led

under pressure to the crankshaft. The main bearings are lubricated by

drilled passages in the main bearing saddles. The oil is forced through

drilled passages in the crankshaft and the connecting rod to lubricate the

crankpin bearings, crosshead pin bushing, and the crosshead slide.

Pressure circulation systems are equipped with suction strainers and

pressure relief or control valves. Oil filters, usually of the full-flow type,

and pressure gauges are also provided. On larger machines where large

quantities of oil are being circulated, oil coolers are provided. Oil pres-

sure safety devices are incorporated in the system to shut the compressor

down in the event of oil pressure failure.

Compressor crankcases are designed to exclude dust and other

contaminants and to prevent oil leakage. All access openings have tight

OIL M reo ttNQCR Mtsmmt

•MOtS

FIGURE 3-2. Full pressure circulating lubrication system (Source: Dresser-

Rand, Painted Post, New York).