Page 283 - Reciprocating Compressors Operation Maintenance

P. 283

268 Reciprocating Compressors: Operation and Maintenance

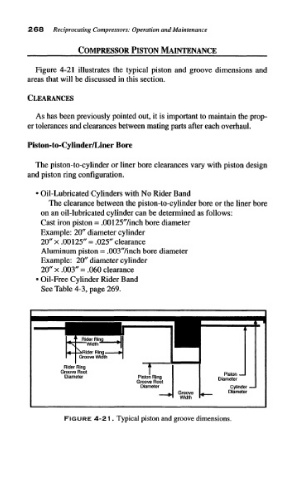

Figure 4-21 illustrates the typical piston and groove dimensions and

areas that will be discussed in this section.

CLEARANCES

As has been previously pointed out, it is important to maintain the prop-

er tolerances and clearances between mating parts after each overhaul.

Piston-to-Cylinder/Liner Bore

The piston-to-cylinder or liner bore clearances vary with piston design

and piston ring configuration.

• Oil-Lubricated Cylinders with No Rider Band

The clearance between the piston-to-cylinder bore or the liner bore

on an oil-lubricated cylinder can be determined as follows:

Cast iron piston = .00125'Vinch bore diameter

Example: 20" diameter cylinder

20" x .00125" = .025" clearance

Aluminum piston = .003"/inch bore diameter

Example: 20" diameter cylinder

20" x .003" = .060 clearance

«Oil-Free Cylinder Rider Band

See Table 4-3, page 269.

FIGURE 4-21. Typical piston and groove dimensions.