Page 288 - Reciprocating Compressors Operation Maintenance

P. 288

Overhaul and Repair of Reciprocating Compressors 273

I _» «~ End Clearance f

\\ End Clearance i

FIGURE 4-27. Butt or step joints in piston rings.

Multiply Value

In Table x .71

Multiply Value

~ &X.87

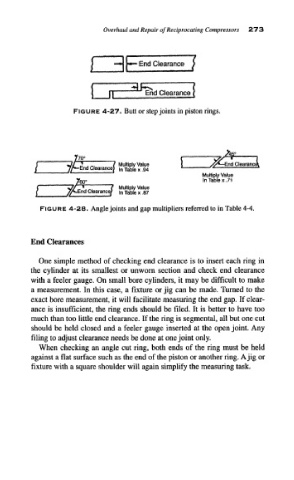

FIGURE 4-28. Angle joints and gap multipliers referred to in Table 4-4.

End Clearances

One simple method of checking end clearance is to insert each ring in

the cylinder at its smallest or unworn section and check end clearance

with a feeler gauge. On small bore cylinders, it may be difficult to make

a measurement. In this case, a fixture or jig can be made. Turned to the

exact bore measurement, it will facilitate measuring the end gap. If clear-

ance is insufficient, the ring ends should be filed. It is better to have too

much than too little end clearance. If the ring is segmental, all but one cut

should be held closed and a feeler gauge inserted at the open joint. Any

filing to adjust clearance needs be done at one joint only.

When checking an angle cut ring, both ends of the ring must be held

against a flat surface such as the end of the piston or another ring. A jig or

fixture with a square shoulder will again simplify the measuring task.